Your cart is currently empty.

On the hunt for top-notch waterproof stickers in NZ? The secret lies in a simple but powerful trio: tough vinyl, weatherproof inks, and a protective laminate. This is the combination that guarantees your designs can handle everything New Zealand's climate throws at them, from scorching UV rays to relentless rain.

Why Quality Matters for Waterproof Stickers in NZ

In a country famous for having four seasons in one day, a regular paper sticker just doesn't stand a chance. A genuine waterproof sticker isn't merely a piece of paper with a bit of gloss; it's a seriously resilient piece of gear, engineered to last. Think of it less like a disposable accessory and more like a long-term tool for branding, safety, or just showing off your style.

The heart of any good waterproof sticker is the material it's made from. Premium vinyl is the industry benchmark for a reason—it naturally shrugs off water and refuses to tear. Couple that with modern printing tech that basically fuses the ink to the vinyl, and you get a design that won’t fade, peel, or bleed, even after months out in the elements.

Built for the Kiwi Environment

From the sticky summers up in Northland to the frosty winter mornings down in Otago, New Zealand’s weather is the ultimate test for any outdoor product. A quality waterproof sticker is specifically made to handle these wild swings.

- UV Resistance: A good laminate is like sunscreen for your sticker. It stops the harsh Kiwi sun from bleaching the colours, keeping them bright and bold.

- Moisture Proofing: The vinyl base and a strong, permanent adhesive mean your sticker stays put, whether it's on a chilly bin at the beach or a kayak cruising Lake Taupō.

- Durability: They're designed to take a beating. Scratches and scuffs are no match, which makes them perfect for high-touch gear like drink bottles, helmets, and tradie utes.

This focus on durability is non-negotiable. A sticker that peels away or fades in a few weeks makes a brand look cheap and ultimately fails at its job. Investing in quality from the start means your message sticks around, delivering real value over the long haul.

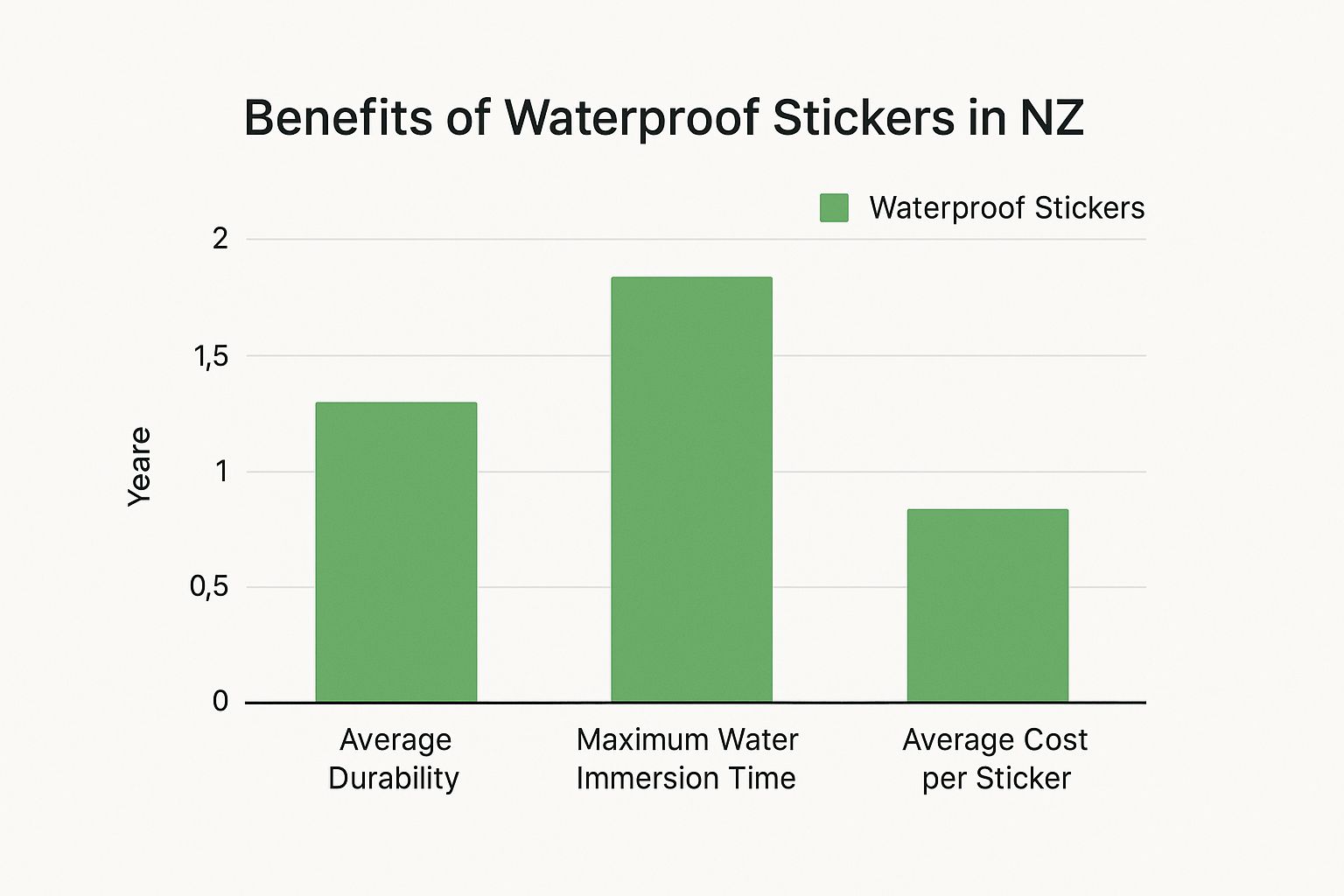

This need for tough, reliable products is reflected in wider market trends. The increasing use of waterproof stickers here in New Zealand for everything from branding to safety compliance is part of a much bigger picture across the Asia-Pacific region, which actually leads the global market for durable labels. You can explore more data on this trend to see how Aotearoa fits into the global scene.

Choosing the Right Material for Your Stickers

Picking the perfect material for your waterproof stickers in NZ is a bit like choosing the right tyres for your car. What you choose will dictate how well they perform, how long they last, and whether they’re right for the Kiwi conditions they’ll face. While you have a few options, the undisputed champion for durability and resilience is high-quality vinyl.

Vinyl is a type of plastic that naturally shrugs off moisture, making it the ideal base for a sticker that needs to last. But its real magic is in its toughness—it resists stretching, tearing, and the harsh New Zealand sun. That means a vinyl sticker slapped on a work ute, a surfboard, or a chilly bin won’t shrink, crack, or fade to nothing after one summer. It’s also flexible enough to hug curved surfaces, giving you a smooth, professional look on everything from drink bottles to helmets.

Beyond Standard Vinyl

While vinyl is the go-to for most jobs, sometimes you need something a little more specialised. Getting to know the alternatives helps you match the material to the mission perfectly.

- Polypropylene: This is a brilliant, budget-friendly option for product labels. It's tough, water-resistant, and perfect for things that live in the fridge or get wet, like craft beer bottles or sauce jars.

- Polyester: If you need something seriously heavy-duty, polyester is your answer. It’s known for its incredible durability and resistance to heat and chemicals, making it a top pick for industrial machinery or equipment. Clear polyester is also great for window decals that look like they’ve been printed right onto the glass.

The key takeaway is simple: the material must match the environment. A sticker for a short-term indoor promo has very different needs from one destined for the bumper of a farm vehicle in rural Canterbury.

To make things clearer, let's break down the most common materials you'll find for waterproof stickers here in New Zealand.

Comparing Common Waterproof Sticker Materials

| Material Type | Key Features | Best For | Durability Rating |

|---|---|---|---|

| Vinyl | Highly durable, flexible, UV-resistant, and excellent for outdoor use. The all-rounder. | Vehicle decals, outdoor gear, window stickers, chilly bins, and general branding. | ⭐⭐⭐⭐⭐ |

| Polypropylene | Cost-effective, tear-resistant, and good moisture resistance. Less flexible than vinyl. | Product labels (food, beverage), short-term indoor or refrigerated applications. | ⭐⭐⭐⭐ |

| Polyester | Extremely tough, heat-resistant, and chemical-resistant. Often used in clear or metallic finishes. | Industrial labels, warning signs, heavy-duty equipment, and high-heat environments. | ⭐⭐⭐⭐⭐ |

Ultimately, while options like polypropylene and polyester have their place, high-quality vinyl remains the most versatile and reliable choice for the vast majority of waterproof sticker needs.

As you can see, the balance of longevity and affordability makes these materials a smart investment for any long-term branding or identification purpose.

Don't Forget the Glue

At the end of the day, your sticker material is only as good as the adhesive holding it down. For a truly waterproof result, you need a permanent adhesive. This kind of glue creates a super-strong bond that won’t give up when it gets hit with rain, condensation, or a good cleaning.

It’s this powerful one-two punch—a durable material like vinyl paired with a seriously sticky adhesive—that makes for a sticker built to last. When you’re placing an order, always double-check that the adhesive is rated for permanent, outdoor use. It’s the only way to guarantee your sticker stays put, no matter what.

How Modern Printing Creates Weatherproof Designs

A sticker's ability to stand up to the elements has as much to do with the printing process as the vinyl it's made from. It's a bit like painting a house to withstand the harsh New Zealand climate; you need the right paint (the ink) and the right technique to make sure it doesn't peel, fade, or wash away in the first downpour. The same logic applies to creating genuinely weatherproof stickers that last.

Modern printers don't just lay ink on top of a surface like your home office machine does. Instead, they use specialised tech to create a powerful chemical bond between the ink and the sticker material. This fusion is what stops the colours from fading, the design from scratching off, and the ink from running when it gets wet.

This advanced approach is what makes waterproof stickers nz businesses and individuals can truly count on.

Key Printing Technologies

Here in New Zealand, printers rely on a few core methods to get that tough, durable finish. While each has its own strengths, they all aim for the same goal: to create a vibrant, long-lasting image that essentially becomes one with the sticker.

- Eco-Solvent Printing: This is a crowd favourite for a reason. It produces stunning, high-resolution images with a fantastic range of colours. The inks use a mild solvent that gently etches into the vinyl, letting the colour pigments sink in and stay put for excellent durability.

- Latex Printing: This method uses water-based inks containing latex polymers, which are then cured with heat. The process creates a flexible, scratch-resistant finish almost instantly, making it a go-to for things like vehicle wraps that need to conform to curves.

- UV Printing: In this process, ultraviolet light is used to cure specially formulated inks the second they hit the vinyl. The result is an incredibly tough, fade-resistant design that can handle the harshest conditions, including direct sunlight and even chemical exposure.

These are the technologies being used locally to ensure Kiwi-made stickers meet high standards for both image quality and colourfastness. This local capability means suppliers can churn out stickers in bulk on massive rolls—sometimes up to 100 metres long—perfect for large-scale commercial jobs. You can get a better sense of the scale by exploring New Zealand's vinyl sticker supply chain.

The Final Layer of Defence: Laminates

For the ultimate protection and to really push a sticker's lifespan to the max, a protective laminate is applied right over the printed design. This is the crucial final step in the weatherproofing process.

Think of a laminate like the clear coat on your car. It’s an invisible shield that takes the hit from UV rays, moisture, scuffs, and scratches, all while keeping the beautiful paintwork underneath safe and sound.

Laminates generally come in two main finishes, giving you a choice in the final look:

- Gloss Laminate: This gives a shiny, vibrant finish that makes colours really pop. It’s highly reflective and adds a premium, polished feel.

- Matte Laminate: This option provides a smooth, non-glare finish for a more subtle, sophisticated look. It's also great for hiding fingerprints and minor scuffs.

No matter which finish you prefer, adding a laminate is the single best thing you can do to make sure your waterproof stickers look great for years.

Real-World Uses for Waterproof Stickers in NZ

The real test of a good sticker isn't just how it looks on the sheet, but how it holds up out in the real world. Across Aotearoa, from a busy city café to a rugged rural farm, waterproof stickers nz are proving their worth every single day. They're more than just bits of sticky paper; they’re hardworking tools for branding, safety, and personal expression.

Think about it. A sticker’s job isn't over once it's applied. It has to survive condensation on a takeaway cup, a high-pressure wash on a digger, or years of sun and salt on a surfboard. That’s where quality materials and printing really shine.

Branding That Braves the Outdoors

For any Kiwi business that lives and breathes the outdoors, waterproof stickers are non-negotiable. They turn everyday gear, products, and vehicles into mobile billboards that can handle whatever our weather throws at them.

Take a surf shop in Raglan, for example. Their logo stickers are slapped on boards, bumpers, and chilly bins, where they’re constantly battered by saltwater, UV rays, and sand. A regular paper sticker wouldn't last five minutes. A properly laminated vinyl one, however, becomes a travelling endorsement for their brand, following customers on every adventure.

You’ll see them everywhere:

- Outdoor Gear: Bold logos on kayaks, skis, and tramping packs.

- Vehicle Branding: On the back of a tradie's ute or a local courier's van.

- Retail Products: As labels on honey jars at the farmer’s market or on craft beer bottles sweating it out in an esky.

Essential Labels for Safety and Industry

Beyond just looking good, waterproof stickers are critical in our industrial and agricultural sectors. In these environments, a label that peels off or fades isn’t just an inconvenience—it can be a safety hazard.

Imagine a bustling construction site. The stickers on hard hats need to stay put in the pouring rain to identify who’s who. Or think about farm machinery that’s constantly covered in mud, moisture, and chemicals. Warning labels and operating instructions have to stay readable. This is exactly where high-performance polyester or heavy-duty vinyl comes into its own.

In New Zealand's demanding industrial and agricultural fields, stickers aren't just for looks—they're for function. Their resilience ensures that vital information remains exactly where it needs to be, day in and day out.

This isn't just theory; it's happening right now. For instance, companies like Wealleans Allied Petroleum Ltd rely on top-tier waterproof stickers to label farm fuel tanks, praising their strong adhesion and colourfastness which meet strict industry standards. Even commercial laundries have discovered how well these stickers work for branding and signage in demanding conditions. You can read more about these commercial sticker applications in NZ.

Personal Expression That Lasts

Of course, it’s not all work and no play. Waterproof stickers are a brilliant way for Kiwis to put their own stamp on their gear and show off what they love. They’re perfect for decorating things that get a lot of handling or spend time outside.

- Drink Bottles and Laptops: Adding a touch of personality that won’t wash off.

- Helmets and Sporting Gear: Displaying team logos or custom art on bikes, skateboards, and helmets.

- Cars and Campervans: Bumper stickers that share a bit of humour or a favourite holiday spot, surviving countless car washes and rainstorms.

Whether it’s for a nationwide company or just your own drink bottle, the goal is the same: to make a statement that sticks around.

Designing and Ordering Your Custom Stickers

Bringing your vision for custom waterproof stickers in NZ to life is an exciting process, and nailing the design phase is the secret to a fantastic result. Before you even think about hitting 'print', getting your artwork ready will save you a world of headaches and guarantee everything looks crisp and professional.

The first thing to get your head around is the two main types of image files.

Think of it like this: a vector file (you'll see extensions like AI, EPS, or SVG) is like a set of instructions. It's made of mathematical lines and curves, which means you can stretch it to the size of a bus or shrink it to a pinhead, and it will stay perfectly sharp. On the other hand, a raster file (like a JPG, PNG, or GIF) is a grid of tiny coloured squares, or pixels, just like a digital photo. These are great for rich, detailed images, but if you try to make them bigger, they start to look fuzzy and "pixelated." For logos, text, and most clean sticker designs, vector is the way to go.

Preparing Your Artwork for Printing

With your design sorted, a few quick technical checks will ensure a smooth ride from your screen to the printer. These steps are what separate an amateur-looking sticker from a truly professional one. If you're starting from scratch, investing in custom logo design services can give your brand a polished look right out of the gate.

To get that top-quality finish, make sure you follow these simple rules:

- High Resolution is a Must: If you absolutely have to use a raster image, make sure it's at least 300 DPI (dots per inch) at the final size you want to print it. Anything less will look blurry up close.

- Add a 'Bleed': A bleed is just a little bit of extra background colour or pattern that extends past the cut line of your sticker. It's a safety margin that prevents any ugly white slivers from appearing if the cutting machine is off by a fraction of a millimetre.

- Outline Your Fonts: This is a crucial step! Converting your text to outlines (or 'curves') essentially turns the letters into shapes. This means the printer doesn't need to have your specific font installed, and your text will look exactly how you designed it.

Getting your file prepared with a bleed and outlined fonts shows your printer you know what you're doing. It makes their job easier and ensures the final product in your hands is exactly what you had in mind.

Choosing Your Sticker Cut and Style

The last piece of the puzzle is deciding how you want your stickers to be cut. This choice has a huge impact on how they look and how easy they are to use.

You’ll generally come across two main options for custom shapes:

- Die-Cut: This is where the sticker and the paper backing it's on are both cut to the unique shape of your design. The result is a really sharp, standalone sticker that’s perfect for handing out or selling individually.

- Kiss-Cut: With a kiss-cut, only the vinyl sticker layer is cut to your design's shape. The backing paper is left as a standard square or rectangle, which makes the sticker much easier to peel off and protects any fine details until it’s ready to use.

Getting these basics right takes all the guesswork out of the ordering process. It puts you in the driver's seat, ready to confidently order custom waterproof stickers that look amazing and are built to last.

Applying and Caring for Your Stickers

Even the toughest waterproof stickers NZ has to offer need a little care to look their best. Getting the application spot-on from the get-go is the single most important thing you can do to make sure they stick around and look professional for years. It's what creates that powerful bond that’ll stand up to whatever the Kiwi weather throws at it.

Before you even think about peeling that sticker, the surface needs to be perfectly clean. It's just like painting a wall – you wouldn't slap a fresh coat over dust and grime, would you? A quick wipe with a simple mix of isopropyl alcohol and water will clear away any sneaky dirt, oil, or residue. This step is crucial because it lets the adhesive get a proper grip, creating a bond that just won't quit.

The Perfect Application Technique

Right, your surface is clean and bone dry, so you're ready to go. The main mission, especially with larger decals, is to avoid those dreaded air bubbles.

- Start from the Centre: Don't peel the whole backing off at once. Just pull back a small strip and get your sticker positioned perfectly.

- Smooth Outwards: Grab a squeegee, a credit card, or even just your fingers and start smoothing the sticker down. Always work from the centre out towards the edges. This little trick pushes any trapped air out as you go.

- Slow and Steady: Keep peeling the backing away bit by bit as you continue to smooth it down. Rushing is your enemy here.

Give the adhesive 24-48 hours to properly cure before you expose it to heavy rain or give it a wash. This waiting game allows the glue to create its strongest possible bond with the surface.

Long-Term Care for Lasting Vibrancy

So, your sticker is on and looking fantastic. How do you keep it that way? Thankfully, looking after high-quality vinyl stickers couldn't be easier. A gentle hand wash with some soap and water is all it takes to keep them looking sharp.

There are a couple of things to steer clear of, though. High-pressure water blasters at the car wash can be a bit too aggressive and might start lifting the sticker's edges. In the same way, stay away from harsh chemical cleaners or abrasive scourers—they can wreck the protective laminate and cause your awesome design to fade.

Answering Your Top Questions About Waterproof Stickers

When you’re on the hunt for waterproof stickers nz businesses and individuals can trust, a few questions always seem to come up. It makes sense—you want to know you’re getting a product that’s going to hold up, especially in our tough Kiwi conditions. Let's clear up some of the most common queries.

First off, there’s a big misconception that any old vinyl sticker is waterproof straight out of the box. While the vinyl itself won't dissolve in the rain, that’s only half the story. The real test comes down to the ink and any protective layers on top.

A sticker printed on a home office printer might look great at first, but the ink will likely run and smudge at the first sign of moisture. Professionally made waterproof stickers, on the other hand, use specialised inks—like eco-solvent, latex, or UV-cured inks—that bite into the vinyl and don't let go, making them genuinely weatherproof.

How Long Do They Last Outdoors? And Can I Put Them in the Dishwasher?

"How long will it actually last outside?" This is probably the number one question we get, especially with New Zealand's harsh sun. A well-made, UV-laminated waterproof vinyl sticker can easily last 3 to 7 years outdoors. That UV laminate is the secret weapon; think of it like a powerful sunscreen for your sticker, stopping the sun's rays from fading the colours.

Another popular question is whether they can survive a trip through the dishwasher. The good news? Yes, high-quality waterproof stickers are absolutely dishwasher-safe. They’re built to withstand the high temperatures, strong water jets, and detergents without peeling off or losing their vibrancy.

Pro Tip: To get the best results, make sure you stick it onto a clean, smooth surface like glass, metal, or ceramic. Give the adhesive a good 24 hours to fully cure before it faces the dishwasher. This little bit of patience allows the glue to create a super-strong bond that’s built to last.

Ready to create stickers that can handle anything? SONI DESIGN specialises in high-quality, durable waterproof stickers perfect for any application. Visit us at https://www.sonidesign.co.nz to bring your vision to life.

Leave a Comment

Stay home & get your daily

needs from our shop

Start You'r Daily Shopping with Nest Mart

Best prices & offers

Orders $50 or more

Free delivery

24/7 amazing services

Great daily deal

When you sign up

Wide assortment

Mega Discounts

Easy returns

Within 30 days