Your cart is currently empty.

Looking for a reliable sticker maker NZ businesses trust? You've come to the right spot. A great local sticker partner does more than just hit 'print'—they work with you to turn a simple idea into a brilliant branding tool that gets your business seen all over New Zealand.

Your Guide to Finding a Local Sticker Maker in NZ

A custom sticker is so much more than a bit of sticky paper. It's your mini-billboard, a tangible 'thank you' to a customer, and a storyteller all in one. For any Kiwi business, whether you're a cosy café in Wellington or an online store shipping from Auckland, stickers are a fantastic way to make a real connection. They can jazz up plain packaging, turn a company van into a moving ad, or give your products that professional, polished look.

But getting from a design on your screen to a perfect sticker in your hand can feel like a mission. What material should I pick? How do I get my design file ready? Which finish will make my logo really stand out? This guide is here to clear up the confusion and give you a straightforward path to ordering custom stickers right here in New Zealand.

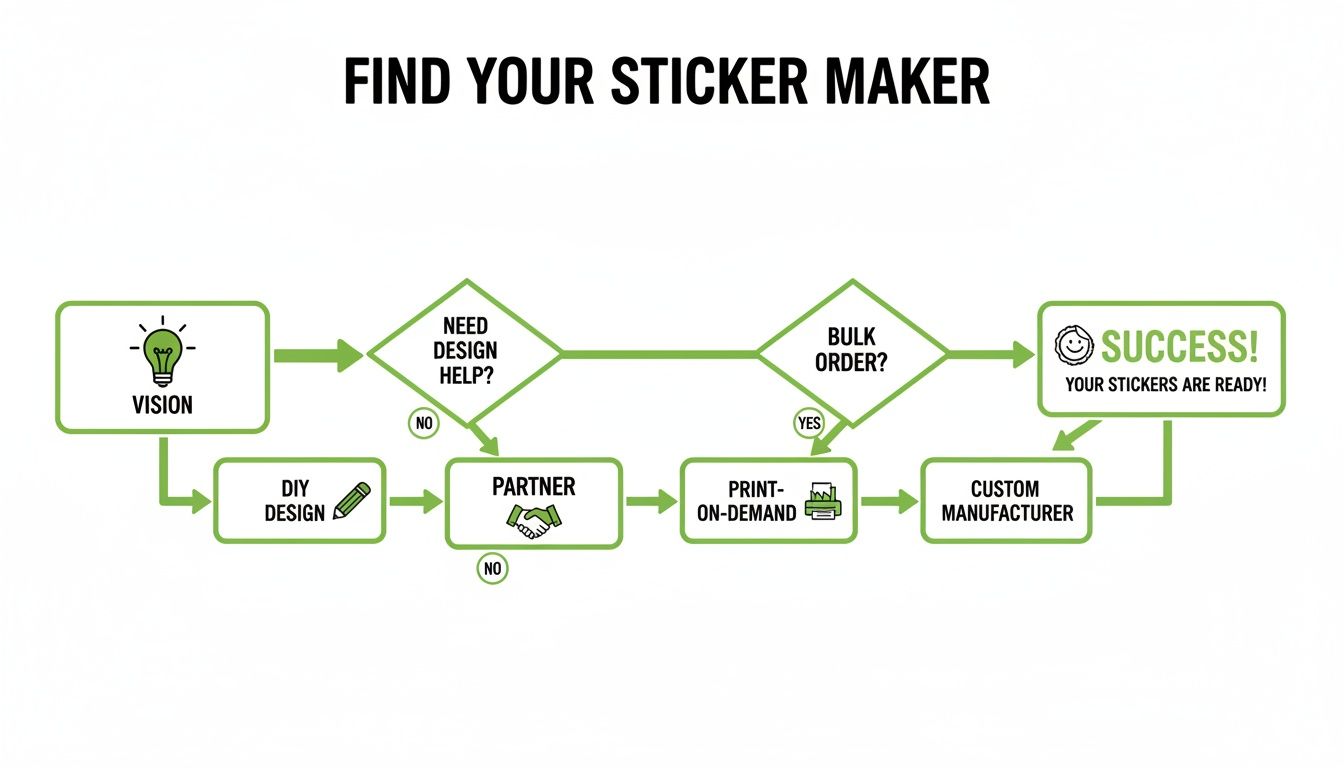

Navigating Your Sticker Journey

Think of choosing a sticker like picking the right tool for a job. You wouldn't use a hammer for a screw, right? In the same way, a paper sticker isn't going to last five minutes on a car bumper, and a super tough vinyl decal is probably a bit much for sealing a paper bag. The goal here is to give you the know-how to pick the perfect sticker for what you need. Finding the right local sticker maker in NZ is a smart way of outsourcing creative services, and this guide will show you how to nail it.

We'll walk you through everything you need to know, step-by-step:

- Sticker Types and Materials: We’ll get into the nitty-gritty of paper versus vinyl and more, so you can choose confidently.

- Finishes and Effects: Glossy? Matte? We'll explain how different finishes change the whole vibe of your sticker.

- Design and File Specs: Get the lowdown on setting up your artwork for a sharp, professional print every single time.

- The NZ Ordering Process: From getting a quote to delivery times, we’ll make the whole process crystal clear.

Here at SONI DESIGN, we're not just a print shop; we're a family-run creative studio that's passionate about great design. We reckon every sticker has a story to tell, and we're here to help you tell yours with punch, personality, and quality.

Whether you're just starting out and need to make a great first impression or you're an established brand looking for a fresh take, you'll find the practical advice you need right here. Let's get started and turn your vision into a sticker that truly sticks.

Choosing the Right Sticker Materials and Finishes

Picking the right material for your custom stickers is probably the most critical decision you'll make in this whole process. It's not just about looks; the material and finish dictate where your sticker can live and for how long. Get this right, and your brand looks sharp, professional, and your money is well spent.

Think of it like choosing between a paper business card and a full-on outdoor sign. One is meant for a brief, indoor impression, while the other has to stand up to whatever the weather throws at it. Your sticker choice follows the exact same logic.

Paper vs. Vinyl: The Great Divide

The first big choice you'll come up against is paper or vinyl. Each has its place, and they are built for completely different jobs. Nailing this fundamental difference is the first step to getting the perfect sticker for your brand.

Paper stickers are the business cards of the sticker world. They're affordable, look brilliant indoors, and are ideal for anything that won't be exposed to moisture or harsh sunlight. They have that classic, slightly textured feel that works beautifully for sprucing up product packaging, sealing envelopes, or as a quick giveaway at a trade show.

Vinyl stickers, on the other hand, are your durable, all-weather warriors. Vinyl is a type of plastic, so it's naturally waterproof, tear-resistant, and tough enough to handle New Zealand’s unpredictable climate. This makes it the only real option for stickers that will live on cars, windows, gear, or anything that gets handled a lot.

This flowchart shows just how simple it can be to take your idea and turn it into a fantastic finished sticker when you have the right partner on your side.

The main takeaway here is pretty clear: a solid idea combined with an expert local partner is the straightest path to a great result.

Unpacking Your Finish Options

Once you've settled on a material, the next step is the finish. This is the laminate, a clear protective layer that goes over the top of the print. It does more than just shield your design from scratches and fading—it completely changes the final look and feel.

A gloss finish is like a fresh coat of polish. It's shiny, vibrant, and makes colours really pop, giving your stickers a high-energy, premium feel. This is a fantastic choice for marketing materials or product labels that need to grab someone's eye on a crowded shelf. A Christchurch real estate agent, for example, might use glossy stickers on their presentation folders for that professional sheen.

On the flip side, a matte finish gives you a modern, subtle, and non-reflective surface. It has a sophisticated, almost soft-to-the-touch quality that’s perfect for elegant branding, minimalist designs, or any sticker that will be seen under bright lights where you want to avoid glare. A high-end candle maker in Queenstown might go for a matte finish to convey a sense of natural, understated luxury.

For anything that's going to live outside for a long time—like vehicle decals or equipment labels—a UV-resistant laminate is an absolute must. Think of it as sunscreen for your sticker; it stops the vibrant colours from fading under our strong Kiwi sun.

Choosing the Right Sticker Material for Your NZ Business

Feeling a bit overwhelmed? Not to worry. This quick comparison table breaks down the basics to help you select the best sticker material for common business needs here in New Zealand.

| Material Type | Best For | Durability | Common NZ Uses |

|---|---|---|---|

| Paper | Indoor, short-term, and dry applications. | Low (not waterproof) | Product packaging, shipping labels, event name tags. |

| Vinyl | Outdoor, long-term, and wet applications. | High (waterproof) | Car decals, window graphics, water bottles, safety signs. |

As you can see, the choice often comes down to where the sticker will end up.

Getting the right combination of material and finish isn't just a technical box to tick; it’s a core part of how you express your brand. For a café in Wellington that needs stickers for their takeaway coffee cups, waterproof vinyl with a gloss finish is the perfect, durable solution.

By working with an expert sticker maker in NZ like SONI DESIGN, you get guidance tailored to your specific goals, ensuring your final product is a perfect fit.

How to Prepare Your Artwork for Printing

A brilliant sticker starts long before it ever touches a printer. It all begins with your digital design file. The truth is, even the best sticker maker in NZ can't work miracles with a blurry or badly prepared image. Nailing this first step is the key to avoiding frustrating delays and ensuring your final stickers look sharp, professional, and exactly like you imagined.

Think of your artwork file as the blueprint for your sticker. If that blueprint is smudged, uses the wrong measurements, or is missing key details, the final product is bound to have problems. This section is your no-nonsense guide to creating a solid blueprint, even if you’re not a graphic designer.

We’ll walk through the essential concepts you need to know, breaking down the technical jargon into simple, practical advice. By the end, you'll know exactly how to prep your files for a perfect print run, every single time.

Vector vs. Raster: The Foundation of Your Design

The first hurdle to clear is understanding the difference between vector and raster images. This choice has a massive impact on how crisp your sticker will look, especially if you ever want to change its size.

Raster images are what most of us are familiar with. They're made up of tiny squares called pixels, just like a digital photo. Common file types like JPEG, PNG, and GIF are all raster-based. They’re great for photos with lots of detail, but they have one major flaw: you can’t resize them without losing quality. If you try to blow up a small raster image, it just gets blurry and pixelated—not a good look for a sticker.

Vector images, on the other hand, are built from mathematical equations that form lines and curves. You'll see them as AI, EPS, and SVG files. Because they aren't pixel-based, you can scale a vector graphic to the size of a billboard, and it will stay perfectly sharp and clear. For this reason, vector is always the best format for logos, text, and illustrations on stickers.

Getting Your Colours Right: CMYK vs. RGB

Ever wondered why the colours on your screen look so different when you print them out? It’s a common frustration, and it usually comes down to the difference between RGB and CMYK colour modes. Luckily, it’s an easy fix once you know what’s going on.

- RGB (Red, Green, Blue) is the colour language of digital screens. Your phone, monitor, and TV all use RGB light to create the colours you see.

- CMYK (Cyan, Magenta, Yellow, Black) is the colour language of printing. It’s all about mixing ink on paper to produce colours.

To make sure your brand colours look just right, your design file must be set to CMYK mode before you send it to us. If you send an RGB file, our software has to guess at the conversion, which can lead to some unexpected and disappointing colour shifts.

Essential Print Concepts: Bleed and Trim Lines

To get that clean, edge-to-edge colour on your stickers, we need to talk about two final, crucial elements: the trim line and the bleed. Getting this right is what separates a professional-looking sticker from one with awkward white slivers around the border.

Think back to colouring-in books. The trim line is the printed black line you’re trying to stay inside of.

Now, imagine a cutting machine trimming thousands of stickers—it’s incredibly precise, but can be off by a tiny fraction of a millimetre. To prevent a white gap from showing up, you need to colour a little bit outside the lines. That extra bit of colour you add is called the bleed.

Most printers in New Zealand, including us here at SONI DESIGN, require a 3mm bleed on all sides of your artwork. This just means extending your background colour or image 3mm past the final cut line. It’s a tiny detail that makes a world of difference. It’s also a good idea to keep any important text or logos inside a "safe zone," usually another 3mm inside the trim line, just to be sure nothing important gets accidentally chopped off.

The Local Sticker Production Process in New Zealand

Once your design file is ready, you hand it over to your chosen sticker maker here in NZ, and that’s where the real magic begins. Getting a handle on this next stage—how your digital idea becomes a physical sticker—is a huge advantage. It lets you plan your product launches, marketing campaigns, and events with real confidence because you know exactly what’s happening and when.

When you partner with a local Kiwi supplier like SONI DESIGN, you’re not just ordering a product; you’re tapping into a seriously capable local industry. You get a partner who gets the nuances of NZ logistics and is just a phone call away. Honestly, that local connection makes everything faster, more collaborative, and way more reliable than dealing with an anonymous overseas factory.

From Digital File to Finished Sticker

The journey from your approved artwork to a box of freshly printed stickers is a well-oiled machine. While the specific equipment might differ between printers, the core steps are pretty much the same across the board. This is how we maintain quality control at every point, making sure the final product is perfect.

Here’s a quick look at what happens behind the scenes after you give us the green light:

- Final File Check: First up, our team gives your artwork one last expert look-over. We’re checking that the resolution, colours (making sure it’s CMYK), and bleed are all spot-on for our printers.

- Printing: Your designs are then printed onto large sheets of the material you’ve picked, whether that's tough-as-nails vinyl or classic paper stock.

- Laminating: If you've opted for a finish like gloss or matte, this is when we apply a protective laminate over the printed sheets. This step adds durability and gives your stickers that final look and feel.

- Cutting: From there, the sheets are moved to a cutting machine that precisely kiss cuts or die cuts each individual sticker into its final shape.

- Quality Control & Packing: Lastly, we give the stickers a final quality check, count them up, and carefully package them so they’re ready to be sent straight to you.

Turnaround Times and NZ Shipping

One of the best things about working with a local sticker maker NZ businesses can rely on is speed. You get to skip the headaches of international shipping and customs queues, which means your order lands in your hands so much faster.

A typical sticker order in New Zealand, from the moment you approve your design proof to having the stickers delivered, usually takes between 5 to 8 business days. That timeframe includes both production and nationwide shipping.

Of course, timing can change depending on the job. A massive order of 10,000 fiddly die-cut stickers will naturally take a bit longer than a simple run of 250 round labels. At SONI DESIGN, we’re all about transparency—we’ll always give you a clear and realistic timeline with your quote, so there are never any last-minute surprises. It doesn’t matter if you’re in a busy Auckland office or a remote spot on the South Island; our courier partners will get your order to you promptly and safely.

By supporting a local printer, you're also putting money back into a key part of our national economy. The wider printing industry in New Zealand, including labels and stickers, has been a strong, reliable sector for decades. This local strength means that even when global supply chains get messy, domestic production keeps ticking along. You can dive deeper into the strength of NZ's manufacturing sector if you’re curious. It's this resilience that gives Kiwi businesses the peace of mind they need to keep their own operations running smoothly.

How NZ Businesses Use Stickers for Brand Growth

Okay, we've talked about the nuts and bolts – the materials, the files, the finishes. But let's get to the exciting part: why custom stickers are such a brilliant tool for Kiwi businesses in the first place. A great sticker is so much more than just a sticky label. It's a mini-billboard, a conversation starter, and a physical piece of your brand that your customers can literally take home with them.

When you find a local sticker maker NZ businesses rely on, you're not just buying a product; you're investing in brand exposure that keeps on giving. Think about it – a digital ad is gone in a flash, but a sticker on a laptop, a KeepCup, or a car bumper gets seen over and over. It’s about turning your loyal customers into brand ambassadors, one sticker at a time.

This simple, low-cost tool can deliver a serious punch when it comes to brand recognition and customer loyalty. Let’s dive into how Kiwi businesses are making stickers work for them.

Real-World Impact Across NZ Industries

The beauty of stickers is their sheer versatility. They can be adapted for just about any business or goal you can think of. Whether it's a subtle touch to make your packaging feel premium or a bold statement on the company ute, the possibilities are endless.

Here are a few real-world examples of how we see our clients at SONI DESIGN using stickers to grow their businesses.

- The Local Café: A bustling Dunedin café pops one of our durable, waterproof vinyl stickers on every single takeaway coffee cup. Suddenly, that morning flat white becomes a mobile ad. Customers carry the café's logo all over town, essentially becoming walking billboards for the business.

- The Tradie's Ute: A plumber based in Tauranga came to us for a large, UV-resistant vinyl decal for the back of his work ute. That one professional, weather-proof sticker now works as a 24/7 advertisement, pulling in leads from potential clients right in the neighbourhoods he’s already working in.

- The E-commerce Store: An online clothing boutique shipping out from Christchurch uses a beautifully designed paper sticker to seal the tissue paper on every order. It’s a small detail, but it completely transforms the unboxing experience, makes customers feel special, and often gets them sharing their haul on social media.

These scenarios show how a small, smart investment can turn everyday items into powerful marketing tools.

Keeping Your Brand Fresh and Relevant

In today's market, looking current is non-negotiable. Here in New Zealand, we see design trends for things like stickers turn over roughly every 12 to 18 months. This doesn't mean you need a total rebrand, but it does mean that savvy businesses often commission new promotional stickers or product labels every couple of years. It’s especially true for seasonal campaigns, where short-run stickers are perfect.

Regularly refreshing your sticker designs is one of the most cost-effective ways to update your brand's look. It's far cheaper than a full rebrand but can have a similar impact, showing customers that your business is dynamic and modern.

This approach lets you play with new slogans, different colour schemes, or seasonal promotions without committing to a massive, expensive overhaul. It’s a flexible way to keep your branding interesting. If you're looking at the bigger picture of business growth, understanding how to measure your marketing efforts is key. Resources on Benchmarking in Marketing for Business Growth can help you see how a simple tool like stickers fits into your overall strategy.

Working with SONI DESIGN

Choosing a sticker supplier is a big decision. You're not just looking for a printer; you're looking for a partner, someone who gets what your brand is all about and genuinely wants to see you succeed. As a family-run creative studio right here in New Zealand, we live and breathe this stuff. For us, every sticker tells a story, and our passion isn't just about ink and vinyl—it's about helping Kiwi businesses like yours tell their stories with a bit of personality.

We know that ordering custom stickers can feel a little daunting, especially if you're not a designer. That's why we're here. Our whole process is built around making it simple, straightforward, and even fun, guiding you from a rough idea to a finished product you'll be proud of.

How We Work With You

When you come to us, you’re never just another order number in a queue. We take the time to really understand what you're trying to do, which means the final product won't just look good—it'll be a perfect fit for your brand and your goals.

Here’s a look at what you can expect when you partner with a dedicated sticker maker in NZ like us:

- The First Chat: It all kicks off with a simple conversation. We'll talk about your ideas, where you plan to use the stickers, and what you hope they'll achieve for your business.

- Design Help: Got a print-ready file? Great! Just have a sketch on a napkin? That's great too. Our creative team is here to help you get your artwork looking sharp and ready for print.

- Digital Proof: Before a single thing is printed, we’ll send over a digital proof. This is your chance to double-check every detail—colours, spelling, placement—and make sure it’s absolutely perfect.

- Printing Magic: Once you give us the thumbs-up, our production team gets to work. We use top-quality materials and printing methods to bring your vision to life.

At SONI DESIGN, our real value lies in mixing creative design smarts with top-notch printing. We don’t just hit 'print' on your file; we work with you to create a powerful branding tool that helps you connect with your customers.

Kiwis love stickers. There's a real appetite for them here, whether for personal expression or for branding, and it's only getting stronger. That means local production has to be on point, allowing creative studios like ours to offer scalable printing and truly tailored design for businesses of all sizes. You can read more about the trends in the NZ sticker market.

Ready to get started? Let’s create something amazing together. Get in touch with our team today for a custom quote and see what a difference working with a local team that truly cares can make.

Got Questions About Custom Stickers? We've Got Answers

Stepping into the world of custom stickers can bring up a few questions, and that's completely normal. You want to get it right for your New Zealand business, and we're here to make that happen. We've pulled together the most common things we get asked by our clients to give you clear, straight-up answers.

This way, you can plan your order with total confidence and know exactly what you're getting when you work with a local Kiwi sticker maker.

What’s the Smallest Order You Can Do?

This is a big one for everyone, from a startup testing the waters with a new product to a big brand needing a massive run for a campaign. The great news is that modern digital printing has completely changed the game, making small orders super affordable. Forget about having to meet a huge, scary minimum.

We can run a small batch of just 50 stickers for a limited-edition product, or print tens of thousands for a nationwide giveaway. Because digital printing doesn't need expensive setup plates like the old-school methods, we can be really flexible to suit your budget and exactly what you need.

How Quickly Can I Get My Stickers?

This is where working with a local sticker maker NZ businesses trust really pays off. You get to dodge all the headaches and long delays that come with international shipping. Once you give us the final thumbs-up on your design proof, things move pretty quickly.

Here’s a rough idea of the timeline:

- Proofing: We'll fire a digital proof back to you for approval within 1-2 business days.

- Production: Once you're happy with it, printing and finishing your stickers usually takes 3-5 business days.

- Shipping in NZ: Courier delivery across New Zealand is typically another 1-2 business days.

So, all up, you could realistically have your finished stickers in your hands in about a week. It makes planning your marketing and product launches a whole lot easier.

Can You Help Me with the Design?

Of course! We know not every business owner is a graphic designer, and that’s totally fine. A brilliant sticker always starts with a brilliant design, and our in-house creative team is here to make sure your artwork is spot on.

Whether you have a print-ready file that just needs a quick once-over, or you’re starting from a sketch on the back of a napkin, we can help. Our team can handle minor file tweaks, convert colours to print perfectly, or collaborate with you to build a brand-new design from scratch.

We see it as a team effort. We’ll work with you to make sure the final design not only looks amazing but truly captures your brand and connects with your customers.

Which Sticker is Best for the NZ Outdoors?

New Zealand's weather is no joke. Between the harsh UV rays, sideways rain, and fluctuating temperatures, any sticker that lives outside on a vehicle, window, or piece of gear has to be tough. No compromises.

For this job, we always recommend our weatherproof vinyl stickers. The material itself is waterproof and won't tear easily. But the real secret sauce is the UV-protective laminate we finish it with. Think of it like a powerful sunscreen for your sticker; it stops the vibrant colours from fading under the Kiwi sun, keeping your brand looking sharp for years.

Ready to turn your sticker idea into something real with a team that gets what NZ businesses need? At SONI DESIGN, we blend creative passion with printing know-how to make stickers that truly stand out.

Leave a Comment

Stay home & get your daily

needs from our shop

Start You'r Daily Shopping with Nest Mart

Best prices & offers

Orders $50 or more

Free delivery

24/7 amazing services

Great daily deal

When you sign up

Wide assortment

Mega Discounts

Easy returns

Within 30 days