Your cart is currently empty.

When you're looking for the right partner for printing labels in NZ, you're doing more than just putting a name on a package. It’s a crucial step in making your product truly stand out on a crowded shelf. It's about picking materials that last, finishes that catch the eye, and a design that tells your brand's story in a heartbeat.

This guide will walk you through everything you need to know to transform a simple sticker into one of your most effective sales tools.

Why Quality Labels Matter for Your NZ Business

In a competitive market, your product's label is its first handshake with a potential customer. It instantly communicates quality, professionalism, and essential information. For Kiwi businesses—whether you're an artisanal food producer in Hawke's Bay or a boutique winery in Marlborough—a well-crafted label is like a silent salesperson, working 24/7 on your behalf.

But it's not just about looking good. A great label has to do some serious heavy lifting to earn its place in the New Zealand market.

Core Functions of a Professional Label

- Your Brand's Ambassador: It’s a vital piece of your branding puzzle, reinforcing your logo, colours, and the unique personality of your business.

- The Information Hub: It clearly lays out all the necessary details, from ingredients and instructions to the compliance information required by NZ regulations.

- The Shelf-Stopper: A striking design can be the one thing that makes a customer choose your product over a competitor's, right at that critical moment of decision.

It's an interesting time for the printing world. While the broader industry has seen some changes, the demand for specialised label printing is booming. The general printing sector in New Zealand actually saw its revenue shrink by about 4.8% annually through 2022-23. However, the surge in e-commerce and local manufacturing has created huge growth in packaging and labels, where presentation is everything. You can explore more data on NZ printing industry trends to see this playing out.

Think of your label as the cover of a book. It’s not just an add-on; it’s an integral part of your product’s perceived value. It can either draw someone in for a closer look or make them walk right on by.

Ultimately, investing in professional label printing isn’t just another cost. It’s a smart investment in your brand's future, ensuring your products not only meet local standards but also connect with customers, build trust, and drive sales.

Choosing the Right Materials and Adhesives

The material and adhesive you choose are the very foundation of a great label. Think of it like picking the right fabric for a piece of clothing – the choice dictates how it performs, feels, and stands up to the elements. Getting this combination right is a crucial step when printing labels in NZ, making sure your product looks professional and the branding stays put.

This decision really does affect your label's lifespan and how well it reflects your brand's quality. A flimsy, peeling label can scream 'low-quality product,' while a durable, well-stuck label builds trust before your customer has even opened the package.

Common Label Materials Explained

Kiwi label printers have a massive range of materials on offer, and each one has its own ideal use. Knowing the difference between them is the key to making a smart choice. Most options fall into two main camps: traditional paper stocks and tougher synthetic alternatives.

Here are some of the most popular choices you’ll come across:

- Uncoated Paper: This stock has a lovely natural, matte texture. It feels like a comfortable cotton shirt – just right for organic, artisanal, or rustic products where that tactile, earthy feel is part of the story. It’s also fantastic for writing on.

- Gloss Paper: A classic for a reason. This option has a smooth, shiny finish that makes colours pop. It's a versatile and budget-friendly choice for a huge range of indoor products, from food jars in the pantry to promotional stickers.

- Polypropylene (PP): A durable plastic that’s resistant to water, oil, and tearing. You’ll see this everywhere on cosmetics, beverages, and food products that might get wet or handled a lot. It comes in clear, white, or even a metallic silver finish.

- Vinyl: Think of vinyl as the ultimate raincoat for your product. It’s the go-to for toughness, offering serious resistance to water, UV light, and chemicals. This makes it perfect for outdoor gear, vehicle stickers, or anything exposed to harsh conditions.

Decoding Adhesives: The Glue That Holds It All Together

The adhesive is every bit as important as the material it’s on. It’s the unsung hero that ensures your label stays exactly where you put it. The wrong adhesive can lead to labels falling off in the cold or, just as bad, leaving a sticky mess behind.

Choosing the right adhesive isn't just about stickiness; it's about matching the label's "grip" to the product's entire life cycle—from your production line to the customer's home.

Let’s look at the three main types of adhesives for your labels:

- Permanent: This is your everyday workhorse, designed to create a strong, lasting bond. Once it’s on, it’s not coming off without a fight, and it will probably tear the label or leave residue behind. It's the standard for most products you see on a shop shelf.

- Removable: Need a label that peels away cleanly? Removable adhesive is your answer. It’s ideal for temporary price tags, promotional stickers on book covers, or labels on glassware that you don’t want to leave a sticky mess on.

- Freezer-Grade: Standard adhesives often give up in cold, damp environments. Freezer-grade adhesive is specifically designed to keep its grip in sub-zero temperatures, making it essential for frozen foods, chilled drinks, and other items that live in the cold.

Using Finishes and Embellishments to Stand Out

Once you’ve locked in the perfect material for your label, the next step is the finish. This is where a simple sticker transforms into a genuine brand experience. It’s a subtle but powerful way to communicate quality, luxury, or an earthy, natural feel before your customer even reads a single word. This is the secret sauce that makes professional printing labels nz so impactful.

Think of it like this: a high-gloss finish is the freshly polished sports car on the shelf—sleek, modern, and impossible to ignore. A soft-touch matte finish, on the other hand, feels like fine suede. It invites people to pick up the product, suggesting a premium, organic quality through touch alone.

Elevating Your Brand with Popular Finishes

The right finish doesn't just look good; it also adds a crucial layer of durability. It protects your design from scuffs, moisture, and fading, ensuring your product looks just as good in the customer's home as it did on the production line. Let's look at a couple of popular choices that can really make your product pop.

-

Lamination: This is a classic for a reason. A thin plastic film is applied over the printed label, available in a vibrant gloss or an elegant, non-reflective matte. Lamination is a real workhorse, giving you fantastic protection against moisture and general wear and tear.

-

UV Varnish: Think of this as a precision tool. A liquid coating is applied to specific parts of your label and then cured instantly with ultraviolet light. A spot UV varnish is perfect for creating a stunning contrast between matte and gloss textures, making a logo or key design element literally shine.

Both of these are fantastic options that balance aesthetic appeal with practical protection.

Adding a Touch of Luxury with Embellishments

If you're aiming for that truly premium feel, embellishments are the way to go. They add texture, shine, and a sense of sophisticated craftsmanship that can dramatically lift your product's perceived value and help justify a higher price point.

An embellishment like foiling or embossing does more than just decorate; it engages multiple senses. The way light catches on a metallic detail or the feel of a raised logo creates a lasting impression that a standard flat print simply cannot match.

Here are a couple of game-changing embellishments to consider:

-

Hot Foil Stamping: This process uses heat and pressure to bond a metallic or coloured foil to your label. Gold, silver, and copper are timeless choices for creating a sense of luxury, making them perfect for high-end products like wine, spirits, or boutique cosmetics.

-

Embossing & Debossing: These techniques add a sophisticated, three-dimensional element. Embossing raises a part of your design up from the surface, while debossing impresses it into the label stock. Both encourage customers to touch and interact with your product.

Imagine a local honey producer using a natural, textured paper with a subtle debossed logo to quietly communicate its artisan origins. Then picture a craft gin distillery using a striking silver foil on a clear bottle to create a modern, unforgettable look. It’s these thoughtful details that separate good labels from truly great ones.

Finding the Right NZ Label Printing Partner

Choosing who will be printing your labels in NZ is one of those decisions that can make or break your product's launch. It’s not just about getting a good price; it’s about finding a partner who gets what you’re trying to do and can deliver top-notch quality, every single time. Get this relationship right, and everything else falls into place.

This is especially true here in New Zealand. The local printing scene has been consolidating, with the number of businesses shrinking to just 774 in 2024. That's a 3.4% drop in one year, which tells you the market is tight. Navigating this landscape means picking your partner carefully. For a deeper dive, check out the data on the NZ printing business landscape.

Key Questions to Ask Potential Printers

Before you sign on the dotted line, you need to vet any potential printer. Think of it like a job interview for a key member of your team, because that’s what they’ll become.

Here are the non-negotiable questions to ask upfront:

- What’s your Minimum Order Quantity (MOQ)? If you’re a small business or just testing the waters with a new product, this is the first hurdle.

- What are your typical turnaround times? This will dictate your own production timeline and help you avoid those heart-stopping, last-minute rushes.

- Can I see and feel physical samples of your work? A PDF proof on a screen can be deceiving. You need to hold their labels in your hand to judge the material and finish properly.

- How do you handle quality control? A good printer will have a clear, step-by-step process for making sure your colours are spot-on and the quality is consistent from the first label to the last.

Here’s a pro tip: working with a local NZ printer usually makes this whole back-and-forth much easier. Communication is quicker, shipping is cheaper, and you’re keeping your money in the local economy. That local connection is a lifesaver when you need a quick change or a fast reprint.

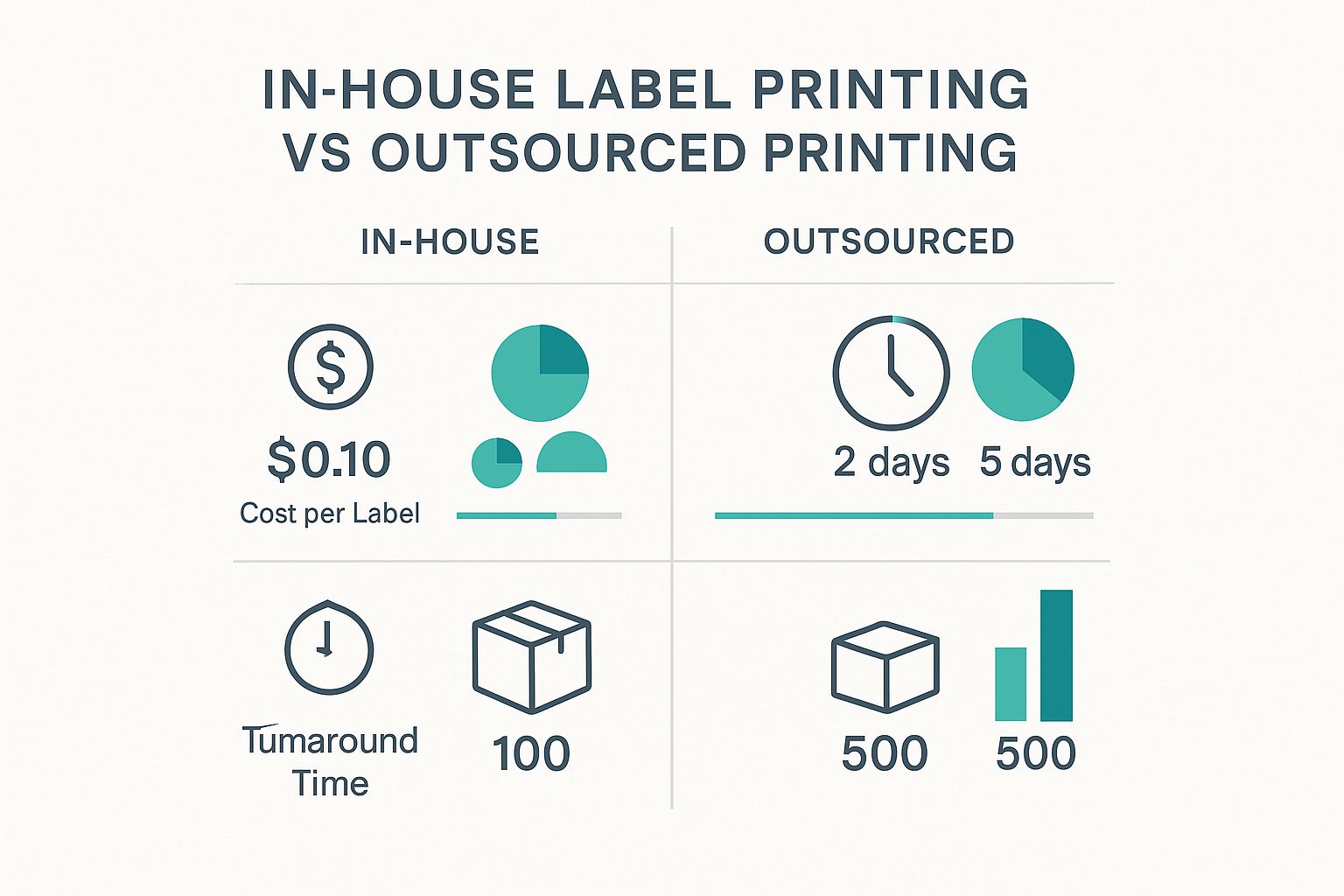

Outsourced vs. In-House Printing

While most businesses outsource their label printing, the idea of doing it in-house can be tempting. The image below breaks down the key differences between partnering with a professional NZ service and going it alone.

As you can see, outsourcing to a pro gives you access to better equipment and a wider variety of materials, often at a much lower cost per label when you’re ordering in bulk.

Digital vs. Flexographic Printing

Finally, it pays to know a little about the technology behind the scenes. Most Kiwi printers use one of two main methods: digital or flexographic. Each has its own strengths, and knowing the difference helps you have a more intelligent conversation with your printer.

To make it simple, here’s a quick breakdown of how they stack up.

Comparing Label Printing Technologies

| Feature | Digital Printing | Flexographic Printing |

|---|---|---|

| Best For | Small to medium runs, prototypes | Very large, high-volume runs |

| Design Complexity | Excellent for complex, photo-quality designs and variable data | Better for simpler, spot-colour designs |

| Setup Costs | Low to none | High initial setup (for the printing plates) |

| Per-Label Cost | Cost-effective for small quantities | Extremely low for massive quantities |

| Turnaround | Fast | Slower due to setup |

Essentially, digital printing is your go-to for smaller batches, intricate designs, or when you need every label to be slightly different (like with serial numbers). On the other hand, flexographic printing is the workhorse for huge runs where you need thousands of identical labels at the lowest possible price.

By asking these questions and understanding the basics of the technology, you can find a true partner who will help your brand look its absolute best.

Designing Effective Labels That Actually Sell

A stunning label that doesn’t actually sell your product is just a pretty piece of paper. The real magic of professional label printing in NZ happens when a great design does more than just look good—it actively drives sales. It's about telling a visual story that is both beautiful and incredibly functional.

This all comes down to mastering a few key elements. Information hierarchy, for example, is just a fancy way of saying you need to guide your customer’s eye to the most important bits first. Think of it as a visual roadmap. Your brand name and what the product is should jump out immediately, so they get the message in a split second.

The Science of Smart Design

Every choice you make, from the font to the colours, sends a subconscious message. Font legibility is absolutely non-negotiable. If a customer has to squint to read your ingredients from a metre away, you've probably lost them. Your font has to be clean and easy to read, even when it's small.

Likewise, colour psychology plays a massive part in how people perceive your product. Studies have shown that colours can nudge people towards a purchase. Green, for instance, often whispers "natural" or "organic," while a sleek black label can suggest a touch of luxury and sophistication. Picking colours that truly reflect your brand's personality is key to making that perfect first impression.

A truly effective label works like a silent salesperson. It not only grabs attention but also answers key questions, builds trust, and makes the final push towards a purchase, all within the space of a few square centimetres.

Your Essential Label Checklist

To make sure your label is working as hard as you are, it needs to include some critical information. This is especially true for food, cosmetic, or therapeutic goods here in New Zealand, where there are specific legal hoops to jump through.

Here’s a practical checklist to get you started:

- Brand Identity: Your logo and brand name need to be front and centre.

- Product Name: Clearly state what’s inside the package.

- Key Details: Don't forget the net weight or volume, a full ingredients list, and any necessary allergen warnings.

- Contact Information: Include your business name and a physical address.

- Country of Origin: Let people know where the product was made or packed.

A great modern touch is the humble QR code. Adding a small QR code can be a gateway, linking customers straight to your website, sharing your brand story, or even offering a special discount. It turns a simple package into an interactive experience. To see how top brands use their packaging for maximum impact, check out these successful PR package examples and get inspired.

Innovations Shaping the Future of Label Printing

The label printing world is moving at a breakneck pace. It’s being pushed forward by some seriously cool new tech and a huge shift in what customers expect from the brands they buy from. For Kiwi businesses, keeping up isn’t just about having a modern-looking label; it's about finding smarter, more responsible ways to connect with people. This is the new frontier for printing labels nz.

One of the biggest waves crashing through the industry right now is sustainability. Shoppers are more aware than ever of packaging waste, and printers are stepping up to the plate. This has sparked a real boom in clever new materials that are kinder to the planet without sacrificing that premium look and feel.

The Rise of Sustainable and Smart Labels

Eco-friendly options are no longer a niche, expensive luxury. They're becoming the go-to choice for businesses of all sizes across New Zealand who want to show they're doing the right thing.

Here are a few of the standout innovations:

- Recycled Materials: Labels made from post-consumer waste are now easy to get and look fantastic. They give you a high-quality finish with a much smaller carbon footprint.

- Compostable Stocks: Think labels made from corn starch or sugarcane. These are designed to break down naturally, making them a perfect match for organic products or brands with an earthy vibe.

- Linerless Labels: The shiny, waxy backing paper you peel off a traditional label is a massive source of waste. Linerless labels do away with it entirely, which can slash waste by as much as 50%.

It's not just about being green, either. Technology is making labels more interactive than ever. Smart labels, which have tiny NFC chips or QR codes embedded in them, can turn your product into a digital experience. Imagine a customer tapping their phone on a wine bottle to get instant tasting notes, or scanning a coffee bag to see a video of the farmers who grew the beans.

These innovations are changing the game. Labels are no longer just static identifiers; they're becoming dynamic tools for telling your brand’s story and keeping the conversation going long after a customer has left the store.

The entire label printing market in New Zealand is showing strong signs of adapting to these changes. Things like digital variable data printing and AI-powered automation are making production faster and more flexible, while the move to linerless is gaining serious traction. You can dig deeper into the stats and trends in the NZ manufacturer print label market to see where things are headed.

All these advancements are giving New Zealand brands powerful new ways to make their mark.

Common Questions About Printing Labels in NZ

Jumping into custom label printing for the first time? It's natural to have a few questions. Getting the details right from the start is the key to making sure the finished product looks exactly how you imagined it and fits within your budget.

Let's run through some of the most common things people ask when they're getting ready to print labels here in New Zealand. These straightforward answers will help you feel confident before you hit "order".

What's the Typical Cost for Printing Custom Labels in NZ?

This is a classic "how long is a piece of string?" question. The cost of labels can swing pretty wildly depending on what you need, a bit like buying a car. The final price tag comes down to four main things: quantity, material, size, and complexity.

A small batch of simple paper labels might only set you back a couple of hundred dollars. But if you’re after a huge run of premium vinyl labels with special touches like metallic foiling, you could be looking at several thousand.

The best way to figure it out? Always ask for detailed, itemised quotes from a few different NZ printers. This lets you compare apples with apples, so you're not just looking at the price but also the quality of materials and the service you're getting.

How Do I Get My Artwork File Ready for a Label Printer?

Getting your artwork print-ready is crucial for a great result. Most printers in NZ will ask for a print-ready PDF file.

There are a few non-negotiables: your file needs to be in CMYK colour mode (not RGB, which is for screens), any images must be high-resolution (at least 300 DPI), and all your fonts should be outlined. Outlining stops the printer's computer from swapping your cool font for a generic one. You'll also need to add bleed (usually 3mm) and a die-line if you have a custom shape. Don't worry, your printer will give you a template or a checklist to follow.

What's the Difference Between Roll and Sheet Labels?

The real difference here is all about how they're supplied and how you're going to use them.

-

Roll Labels: These come, as the name suggests, on a big roll. They're perfect if you're ordering thousands of labels and using a machine to stick them on your products quickly and efficiently.

-

Sheet Labels: These are delivered on flat sheets, like stickers you'd get from a stationery shop. They're a better fit for smaller orders or if you're applying every single label by hand.

The right choice really just depends on how many you need and how they'll end up on your products.

Ready to bring your brand's vision to life with stunning, high-quality labels? The team at SONI DESIGN is here to help. We combine a passion for great design with expert printing knowledge to create labels that tell your story. Find out more at the SONI DESIGN website.

Leave a Comment

Stay home & get your daily

needs from our shop

Start You'r Daily Shopping with Nest Mart

Best prices & offers

Orders $50 or more

Free delivery

24/7 amazing services

Great daily deal

When you sign up

Wide assortment

Mega Discounts

Easy returns

Within 30 days