Your cart is currently empty.

Ever wondered how a restaurant menu survives countless spills or how a business card can feel so sturdy and premium? The secret is often a simple finishing touch: paper lamination. At its core, lamination is the process of bonding a thin plastic film to a printed document, giving it a protective shield. This one step can make paper stronger, more durable, and visually striking, turning a standard print into something built to last.

What Is Paper Lamination and Why Does It Matter?

Think of an unlaminated document like a shirt without a jacket. It's fine indoors, but it’s completely vulnerable to a coffee spill or a sudden downpour. Lamination is that protective jacket. It seals the paper from moisture, grubby fingerprints, and general wear and tear, making sure it stays looking sharp for much, much longer.

The process itself is straightforward: a clear plastic film is applied to one or both sides of the paper. Once it’s bonded, that film acts as a barrier, completely changing the paper's properties. It’s no longer just ink on a page; it’s a tough, resilient tool for your business.

For a quick overview, here are the core advantages lamination brings to the table.

Core Benefits of Lamination at a Glance

| Benefit | Impact on Your Business Materials | Ideal For |

|---|---|---|

| Durability | Reinforces paper, making it resistant to tearing, creasing, and rough handling. | Menus, price lists, instruction manuals, ID cards, and anything handled frequently. |

| Waterproofing | Creates a moisture-proof seal, so spills and rain can be wiped away without damage. | Outdoor signage, restaurant menus, workshop guides, and poolside notices. |

| Visual Enhancement | Deepens colours, sharpens text, and adds a professional sheen or a sophisticated matte finish. | Business cards, presentation folders, book covers, and high-end marketing brochures. |

| Longevity | Drastically extends the life of printed items, reducing the need for costly reprints. | Posters, permanent displays, safety signs, and archival documents. |

| Cleanliness | Prevents stains from dirt, grease, and fingerprints, keeping prints looking pristine. | Educational materials, flip charts, kitchen recipe cards, and any shared documents. |

Ultimately, investing in lamination means your materials work harder for you, for longer.

Enhancing Durability and Longevity

The most obvious win with lamination is the massive boost in durability. A single sheet of paper is fragile—it tears, creases, and stains if you so much as look at it the wrong way. By adding that plastic film, you're reinforcing its structure and giving it a fighting chance against daily life.

Let's break down the practical advantages:

- Tear-Resistance: The plastic adds serious strength, stopping those accidental rips that plague frequently used items like price lists or workshop manuals.

- Spill and Moisture Protection: A laminated surface is completely waterproof. Coffee, rain, you name it—just wipe it off. This is a life-saver for café menus and outdoor flyers.

- Stain and Smudge Prevention: Oily fingerprints, dirt, and ink smudges can't get through the plastic barrier, keeping your documents looking clean and professional.

This incredible durability means your print materials last significantly longer, which saves you the hassle and cost of reprinting. A single laminated poster can easily outlast dozens of unlaminated ones.

Lamination is more than just protection; it's a strategic decision. It ensures your marketing materials, instructional guides, and important documents maintain their quality and effectiveness from the first day to the last.

Improving Brand Perception and Visual Appeal

Protection aside, lamination has a huge impact on the look and feel of your prints. The finish you choose can make colours pop and text appear crisper, creating a much more engaging and polished piece.

A laminated business card feels more substantial in a potential client's hand, immediately conveying a sense of quality and attention to detail. Likewise, a laminated report cover feels more professional than a flimsy paper one. It’s a subtle upgrade, but it shapes how customers see your brand, reinforcing an image of quality and reliability. In short, it’s a small detail that makes a big impression.

Understanding the Main Lamination Methods

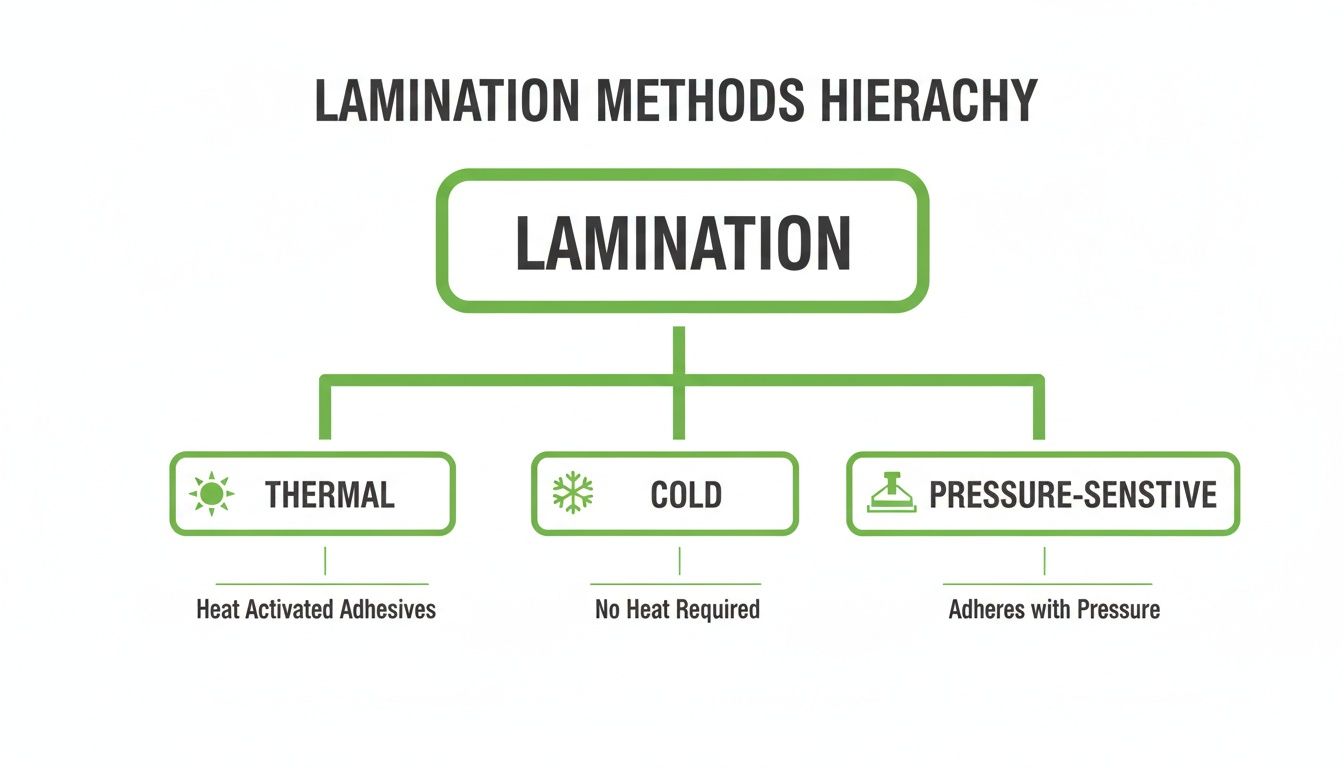

Once you see what lamination can do for your prints, the next logical question is, "How does it actually work?" It’s not a one-size-fits-all process. The way we apply that protective film can change everything, depending on what you’re printing and where it’s going to live. The three main players are thermal, cold, and pressure-sensitive lamination.

Think of it like choosing the right tool for a job. You wouldn't use a sledgehammer to hang a picture frame. In the same way, you wouldn't blast a delicate, vintage photo with intense heat. Let’s break down these techniques so you know exactly what to ask for, whether you're making a tough-as-nails outdoor sign or protecting a heat-sensitive photograph.

Thermal Lamination: The Power of Heat

Thermal lamination, often just called hot lamination, is the workhorse of the professional printing world. It's the most common method you'll come across. The process uses a laminator that heats up a special film coated with a heat-activated adhesive. Your document gets sandwiched between two sheets of this film and fed through hot rollers, which melt the glue and press it all together to create a super strong, permanent bond.

This is the go-to for creating seriously durable and rigid items. The combination of heat and pressure seals the edges completely, giving you fantastic protection against moisture and general wear and tear.

It's a bit like vacuum-sealing your documents for freshness. The heat literally fuses the plastic film to the paper, making an airtight and waterproof barrier. This makes it the perfect choice for anything that needs to survive a bit of a hard life.

- Best For: Things that need maximum durability, like ID cards, restaurant menus, outdoor event passes, and instructional signs.

- Key Benefit: Creates a very strong, rigid, and often completely waterproof seal.

- Consideration: Not suitable for materials that can be damaged by heat, such as certain inks, thermal paper, or delicate photos.

Cold Lamination: A Gentle Approach

Just as the name suggests, cold lamination ditches the heat. Instead, it uses a film that already has a pressure-sensitive adhesive on it. High-pressure rollers are then used to bond the film tightly to the paper. This process is much gentler, which makes it ideal for materials that would warp, melt, or discolour if you put them through a hot laminator.

Imagine applying a high-quality, perfectly smooth protective sticker over your entire document. There's zero risk of heat damage, which means the integrity of any heat-sensitive inks or papers is completely preserved. This makes it a specialist solution for more delicate or valuable items.

Cold lamination is the method of choice for protecting things like original photographs, documents printed with wax-based inks, or synthetic papers that just can't take the heat. It gives you protection without compromising the original print.

While the bond isn't quite as aggressive as what you get with thermal lamination, it still offers excellent protection. For the right job, it's an absolutely essential technique that keeps fragile prints safe.

Pressure-Sensitive Lamination: The Versatile Option

Pressure-sensitive lamination is really a type of cold lamination, but it's worth its own mention because it's so flexible. It works a lot like a sticker or a decal. The film comes with an adhesive backing that’s protected by a release liner. You simply peel off the liner and apply the film using pressure—often with a simple roller or even by hand for smaller jobs.

This method gives you incredible flexibility. It can be applied to just one side or both sides of a document and is perfect for custom shapes, large-format graphics, or any project where hauling out a big laminating machine just isn't practical. Its simplicity makes it a popular choice for everything from protecting book covers to applying floor graphics.

This technique is particularly relevant across New Zealand's commercial sectors. In industries where protective films for things like food packaging and promotional materials are vital, the technology behind lamination plays a huge role. The country's paper and paperboard manufacturing industry, valued at around $1.9 billion, supports the creation of durable laminated products for retail, real estate, and hospitality—all sectors SONI DESIGN serves. Innovations in thin lamination films, especially for packaging, show the demand for protective layers that look great and guard against moisture—a trend that directly benefits businesses creating everything from menus to marketing materials. You can read more about the trends in the lamination machine market.

Ultimately, getting your head around these core methods means you can have a much more informed conversation with your print provider. It ensures the final product not only looks fantastic but is perfectly suited for its intended purpose.

Choosing the Perfect Finish for Your Project

While the lamination method is the how, the finish is the wow. This is where you move beyond the technical side and start thinking about the story you want your materials to tell. Choosing the right finish is a creative call that directly shapes how people feel about your brand, turning a simple piece of paper into a memorable experience.

Every finish has its own personality. A high-shine gloss can shout excitement and value from the rooftops, while a muted matte finish whispers sophistication and quality. Getting this right is crucial for matching the final product to your brand's message and the impression you want to leave.

Gloss Lamination for Vibrant Impact

Think of gloss lamination as turning up the volume on your colours. It's a highly reflective, shiny finish that makes images and graphics look incredibly sharp and full of life. It creates a smooth, slick surface that catches the light—and your customer's eye.

The high-contrast effect of a gloss finish makes colours seem deeper and more saturated. It’s the perfect choice when you need your visuals to pop, which is why it's a long-time favourite for promotional materials designed to stand out in a crowded marketplace.

- Look: Bright, shiny, and highly reflective.

- Feel: Smooth and slick.

- Best For: Marketing flyers, brochures, posters, photo prints, and catalogue covers.

- Key Benefit: Maximises colour vibrancy and gives excellent protection against moisture and fingerprints.

If your design is bold and colourful, a gloss finish will make sure it gets noticed. Just keep in mind that its high reflectivity can sometimes create glare under direct lighting, so it might not be the best pick for text-heavy documents.

Matte Lamination for Understated Elegance

In complete contrast to the high energy of gloss, matte lamination offers a soft, non-reflective, and sophisticated look. It provides a smooth, satin-like finish that diffuses light, preventing glare and giving the final piece a more subdued and premium feel. This subtle effect often makes text much easier to read, especially under bright lights.

Matte lamination is all about creating an impression of luxury and quality. It’s the go-to choice for high-end business cards, elegant invitations, and professional reports where the goal is to convey prestige and seriousness.

A matte finish provides a smooth, tactile experience that feels professional and refined. It’s less about shouting for attention and more about quietly communicating class and high value.

This finish is also brilliant for hiding fingerprints and scuffs, keeping your materials looking clean and pristine even after being handled multiple times. It’s the perfect partner for designs that are minimalist, elegant, and focused on beautiful typography.

Soft-Touch Lamination for a Lasting Impression

If you want your printed materials to be genuinely unforgettable, soft-touch lamination is the way to go. This unique finish gives you the low-glare, sophisticated appearance of matte but adds an incredible tactile dimension. It has a velvety, suede-like texture that feels luxurious and almost buttery to the touch.

This finish is designed to engage the sense of touch, encouraging people to hold onto your materials for just a little bit longer. That unique feel makes a powerful statement about your brand's commitment to quality and attention to detail.

- Look: A deep, non-reflective matte appearance.

- Feel: Smooth, velvety, and luxurious.

- Best For: Premium business cards, high-end presentation folders, luxury packaging, and book covers.

While it is the most premium option, the memorable experience it creates can be invaluable. A proposal presented in a soft-touch folder or a business card with this finish doesn't just share information—it creates a lasting, positive connection. The lamination of paper with a soft-touch finish is a definitive mark of a premium brand.

To help you decide, here’s a quick side-by-side look at how these finishes stack up.

Comparing Lamination Finishes

| Finish Type | Visual Appearance | Tactile Feel | Best For |

|---|---|---|---|

| Gloss | High-shine, reflective, vibrant | Smooth, slick | Flyers, posters, photos, brochures |

| Matte | Non-reflective, satin, subdued | Smooth, elegant | Business cards, invitations, reports |

| Soft-Touch | Deep matte, non-reflective | Velvety, suede-like, luxurious | Luxury packaging, premium book covers |

Ultimately, the best finish depends entirely on your project's goals. Whether you need something eye-catching and durable or subtle and sophisticated, there's a lamination finish that will get the job done beautifully.

Before you can get to these incredible finishes, the process has to start with one of the core lamination methods. This chart breaks down the main techniques.

As you can see, the three core techniques—thermal, cold, and pressure-sensitive—form the foundation of all paper lamination.

Real-World Lamination Applications

It’s one thing to know the theory behind lamination, but seeing it solve real-world problems is where it really clicks. Lamination isn’t just a finishing touch; it’s a practical tool that helps businesses look sharp and operate smoothly, turning fragile paper into a tough, reliable asset.

Let’s look at a few everyday scenarios where the right type of lamination makes all the difference.

Hospitality: A Local Café's Secret Weapon

Picture a busy local café. Their menus are handled by hundreds of people every day, getting splattered with coffee, touched by sticky fingers, and caught in the occasional spill. Without protection, those menus would be dog-eared and stained in less than a week. That means constant reprinting costs and a scruffy look that doesn’t do the food justice.

This is exactly where matte lamination shines. By laminating their menus with a matte finish, the café gets a few huge wins:

- Tough and Tidy: Spills and smudges wipe right off, so the menus always look clean and hygienic.

- No More Glare: The matte surface cuts down on reflections from overhead lights, making the menu easy to read from any angle.

- A Touch of Class: The smooth, non-shiny finish just feels more professional and adds a subtle hint of quality to the dining experience.

This simple step saves the café a surprising amount of money on reprinting over the year and keeps their brand looking polished.

Real Estate: Making a Lasting First Impression

Now think about a real estate agent trying to stand out. Their flyers and property brochures are their frontline marketing tools, often left in letterboxes where they’re at the mercy of New Zealand’s famously unpredictable weather. A soggy, wrinkled flyer is not a good look. It instantly cheapens the agent’s image and the property they’re trying to sell.

Smart agents know this, which is why they use gloss-laminated flyers. The high-shine finish makes property photos pop with vibrant colour, but more importantly, it creates a waterproof shield. A gloss-laminated brochure can handle a downpour or morning dew and still look sharp when a potential buyer pulls it out of the letterbox. That durability speaks volumes about professionalism before the agent has even said a word.

In real estate, you don’t get a second chance to make a first impression. A tough, beautifully finished flyer suggests both the agent and their listings are top-notch.

Corporate and Financial Services: Projecting Confidence

Imagine a financial firm putting together a major proposal for a new client. The numbers are solid and the strategy is brilliant, but the document itself has to reflect that. Handing over a report printed on plain paper just feels a bit flat—it doesn’t communicate the weight of the opportunity.

This is a perfect job for soft-touch lamination. Applying this velvety, luxurious finish to the report cover changes everything. It’s no longer just a document; it’s a tactile experience. The unique feel makes the client want to hold it, and the deep matte look screams sophistication. It’s a small detail that helps the proposal feel more significant, building trust and helping to close the deal.

That commitment to quality matters. New Zealand's own pulp, paper, and paperboard manufacturing industry—the source of these materials—has faced revenue declines of about 7.4% annually over the past five years. Despite this, the industry shows its grit through productivity gains. Processes like lamination are key, adding crucial value and durability to paper products used everywhere from finance to healthcare. You can find more details in this report on New Zealand's paper manufacturing industry.

Healthcare and Education: Clear and Clean Communication

Finally, think about a busy medical clinic or a school. They rely on posters, safety notices, and charts in high-traffic areas. These materials need to stay clean and easy to read to be effective, especially when they’re being seen and touched all day long.

Here, a simple and sturdy gloss or matte lamination is a must-have. It means important notices, like hand-washing instructions in a clinic or classroom rules, can be wiped down and disinfected without the ink running or the paper falling apart. Lamination is a small investment that ensures critical information stays clear, bright, and protected for months or even years.

Cost, Durability, and Environmental Factors

Choosing to laminate your prints isn't just about the final look and feel. It’s a practical decision that balances your budget, how long you need the item to last, and your brand's commitment to the environment. Thinking through these factors helps you make a smart call, getting the most value without straying from your company’s principles.

Think of lamination as an investment. Yes, it adds an initial cost to your print run, but the real payoff is in durability. A simple paper menu in a bustling café might only survive a few weeks of spills and handling. A laminated one? It could last for months, maybe even years, saving you a small fortune in reprinting costs down the track.

Breaking Down the Cost

The price of lamination isn't a simple, one-size-fits-all number. It’s influenced by a few key variables that your print partner will use to build your quote. Understanding these helps you see where the money goes and how you can tweak your specs to meet a budget.

- Film Thickness: This is measured in microns (mic). Thicker films mean more protection and rigidity, but they also cost more. A thin 40mic film is perfect for things that need to stay flexible, whereas a heavy 250mic film feels almost like a plastic card.

- Finish Type: As we've covered, different finishes come with different price tags. A standard gloss is usually the most budget-friendly option, with matte following closely behind. Premium finishes like soft-touch are a bit more of a splurge because the film and the process are more specialised.

- Order Volume: Printing is a numbers game. The more you print, the lower the cost per item. A short run of 50 laminated posters will have a much steeper unit cost than a massive order of 5,000.

- Size of the Item: It’s simple maths, really. Bigger items use more material and take longer on the machine, which pushes the price up.

When it comes to protecting something for the long haul, like in preserving vintage posters, the upfront cost of lamination is a no-brainer when you consider the longevity it buys you.

The Environmental Conversation

Let’s be honest about the environmental impact. Traditional lamination films are plastics made from fossil fuels. When you bond that plastic to paper, you create a composite material that’s a real headache for recycling. The plastic and paper are essentially fused together, meaning most laminated paper can't just be tossed into your standard paper recycling bin.

The core environmental challenge is that the plastic and paper can't be easily separated. Once they're bonded, they become a single material that most recycling facilities simply aren't set up to handle.

But it’s not all bad news. The print industry is getting smarter and greener. There's a real push for more sustainable materials, and manufacturers are starting to deliver some great alternatives. These eco-friendly films are designed to be either recyclable or biodegradable, which seriously lessens their footprint.

Making a Sustainable Choice

If sustainability is a big deal for your business, don't write off lamination just yet. The best thing you can do is have an open chat with your print shop about the greener options they have on hand.

Here are a few things to ask about:

- PLA (Polylactic Acid) Films: These are plant-based plastics, often made from corn starch, and are compostable in commercial facilities.

- Cellulose-Based Films: Made from wood pulp, these films are biodegradable and feel much closer to their natural origins than traditional plastic.

These eco-friendly choices might cost a little extra, but they let you get all the protective benefits of lamination while staying true to your environmental goals. It’s all about finding that sweet spot between cost, durability, and sustainability—a balance that is now well within reach.

How to Prepare Your Files for Professional Lamination

Getting a flawless finish when you’re professionally laminating paper starts long before your project ever touches a machine. The single most important thing you can do is submit a properly prepared digital file. Getting this right from the beginning is the key to avoiding frustrating delays and expensive reprints.

Think of your print file like a blueprint for a house. If the blueprint has fuzzy lines or incorrect measurements, you're going to end up with a wonky building. It’s exactly the same with printing; a perfect file gives your print shop all the information they need to deliver a perfect result. This means getting a few technical details spot on.

Setting Up Your Artwork Correctly

First up, you need to get your head around bleed. If your design has any colours, photos, or graphics that go right to the edge of the page, you can't just stop them at the border. You need to extend them slightly beyond the final trim line. This extra margin is the bleed, and it’s usually 3mm on all sides.

Why is this so important? When the laminated sheets are trimmed down to their final size, the bleed gives the guillotine a small margin for error, preventing any ugly, accidental white slivers from appearing along the edges.

Along with bleed, you'll need trim marks. These are tiny lines in the corners of your artwork that show the printer exactly where to make the cut. Together, bleed and trim marks are the secret to that professional, edge-to-edge colour.

Sending a file without bleed is one of the most common mistakes we see. It either forces the printer to send it back, delaying your job, or results in a finished product that just looks amateurish with a white border.

The other big one is image resolution. For sharp, professional printing, all your images need to be high-resolution. That means at least 300 DPI (dots per inch) at the size they will be printed. Grabbing a low-res image off a website might look okay on your screen, but it will come out looking blurry and pixelated on paper, completely ruining the effect of your beautiful laminated finish.

Finalising and Submitting Your File

Once your design is good to go, how you save it makes all the difference. The industry standard for a reason is a print-ready PDF. This file type is brilliant because it locks everything in place—fonts, images, colours, and layout—so it looks exactly the same on the printer’s computer as it does on yours.

To make sure your laminated paper turns out perfectly, it’s always best to follow specific print artwork setup guidelines. Sticking to these standards makes the whole process smoother for everyone.

And while a DIY laminator might seem like a good idea for a one-off job, it's incredibly difficult to avoid bubbles, creases, and dodgy seals. Professional services give you that seamless, durable finish that home methods just can't replicate, making that little bit of file prep a truly worthwhile investment.

Common Questions About Paper Lamination

Diving into the world of print finishing can definitely bring up a few questions. When it comes to the lamination of paper, getting the specifics right is key to making the best choice for your project. To give you complete confidence in the process, we’ve put together answers to some of the most common queries we hear.

We’ll tackle the practical stuff—from material limits to the final look—so you know exactly what to expect.

Can You Laminate Both Sides?

Absolutely, and honestly, most of the time you should. Laminating just one side of a document can cause it to curl over time. This happens because the paper naturally reacts to changes in humidity, and the single-sided film creates an imbalance.

Laminating both sides, a process known as encapsulation, results in a much more balanced and stable product. This method seals the paper completely, giving it maximum protection against moisture and general handling. For anything that needs to be truly durable, like menus or ID cards, two-sided lamination is the way to go.

What Is the Thickest Paper You Can Laminate?

The thickness of the paper you can laminate really depends on two things: the paper stock itself and what the laminating machine can handle. We measure paper weight in grams per square metre (GSM). Generally, most professional print shops can comfortably laminate paper up to 350 GSM, and sometimes even 400 GSM.

It’s all about finding the right balance. If you pair a really thick paper with a very thick lamination film, it can become too rigid and might struggle to feed through the machine properly. It's always a good idea to chat with your print provider to find the perfect pairing for your project.

This ensures you get a smooth, professional finish without putting any stress on the paper or the film.

How Does Lamination Affect Print Colours?

Lamination almost always changes how your print colours look—usually for the better! The specific effect really depends on the finish you choose.

- Gloss Lamination: Think of this finish as a colour amplifier. It makes blacks look deeper, brights pop with more vibrancy, and increases the overall contrast. The result is a dynamic, eye-catching look.

- Matte and Soft-Touch Lamination: These finishes tend to soften colours slightly. They cut down on glare and give the print a more subdued, sophisticated appearance, creating an elegant and premium feel.

Knowing this beforehand helps you pick a finish that perfectly matches the mood you're aiming for with your design.

Is Laminated Paper Truly Waterproof?

This is a key question, and the answer comes down to one detail. A fully encapsulated document—where the laminate extends beyond the edge of the paper to create a sealed border—is completely waterproof. Spills will just bead up on the surface and can be wiped away without causing any damage.

However, if a laminated document is trimmed flush to the paper's edge, it is only water-resistant. Over time, moisture can still find its way into the paper fibres from that unsealed edge. If you need maximum protection against the elements, always ask for an encapsulated finish.

At SONI DESIGN, we're here to guide you through every choice to make sure your final product is perfect. Contact us today to discuss your vision and let's create something extraordinary together!

Leave a Comment

Stay home & get your daily

needs from our shop

Start You'r Daily Shopping with Nest Mart

Best prices & offers

Orders $50 or more

Free delivery

24/7 amazing services

Great daily deal

When you sign up

Wide assortment

Mega Discounts

Easy returns

Within 30 days