Your cart is currently empty.

Ever wondered how to get your own designs onto a t-shirt without any fancy gear? The secret is iron-on print transfer paper. It’s a special coated paper that lets you print a design from your computer using a regular inkjet printer and then transfer it onto fabric with a simple household iron.

It's one of the easiest and most affordable ways to create custom tees, bags, and other textiles right from your kitchen table, which is why it’s become a massive hit with DIY crafters and small businesses all over the country.

Your Guide to DIY Custom Fabric Creations

Welcome to the colourful world of custom apparel, made easy. This guide is your starting block for getting the hang of iron on print transfer paper, a fantastic material for putting your personal stamp on everything from t-shirts and tote bags to cushions and aprons. It’s all about bringing your digital ideas into the real world without needing a bunch of expensive, specialised equipment.

Here in New Zealand, this method has become a go-to for hobbyists and even budding entrepreneurs. It’s a super user-friendly and cheap alternative to more involved methods like screen printing. Think of this as your first step to turning plain, everyday fabrics into one-of-a-kind pieces of art.

The Power of Personalisation

There’s something special about creating something that’s uniquely yours. It’s a way to express yourself, give a truly thoughtful gift, or even get a small brand off the ground. With iron-on transfer paper, you barely need anything to get started. If you’ve got an inkjet printer and an iron, you’re pretty much set.

This simple process really closes the gap between your digital design and a physical product you can hold. The benefits are clear:

- It’s affordable: You can make a single custom item or a small batch without the hefty setup fees that come with professional printing services.

- Total creative freedom: Any high-resolution image you can think of—from a family photo to a detailed piece of graphic art—can be transferred. Your imagination is really the only thing holding you back.

- It’s quick and convenient: You can literally design, print, and press a custom shirt in less than an hour. Perfect for those last-minute gift ideas or merch for an event.

A Thriving Local Market

You can see the Kiwi enthusiasm for DIY projects reflected in the market. The thermal paper market in New Zealand, which includes iron on print transfer paper, was estimated to pull in USD $34.1 million in revenue in 2024. That number shows a real local appetite for craft supplies as more of us get into personalising our clothes and home decor.

This simple tool has revolutionised home crafting by putting the power of a print shop into the hands of everyday creators. It's not just about making a t-shirt; it's about wearing your story.

Ultimately, this guide will walk you through everything you need to know to get professional-looking results every time. And once you've mastered iron-on transfers, there are plenty of other DIY fashion techniques and custom fabric projects out there to expand your crafting skills.

How to Choose the Right Transfer Paper

Getting this first step right is easily the most important part of the whole process. Picking the right iron on print transfer paper is the foundation for a vibrant, durable design. If you get it wrong, you’ll end up with a faded, cracked, or even completely invisible mess.

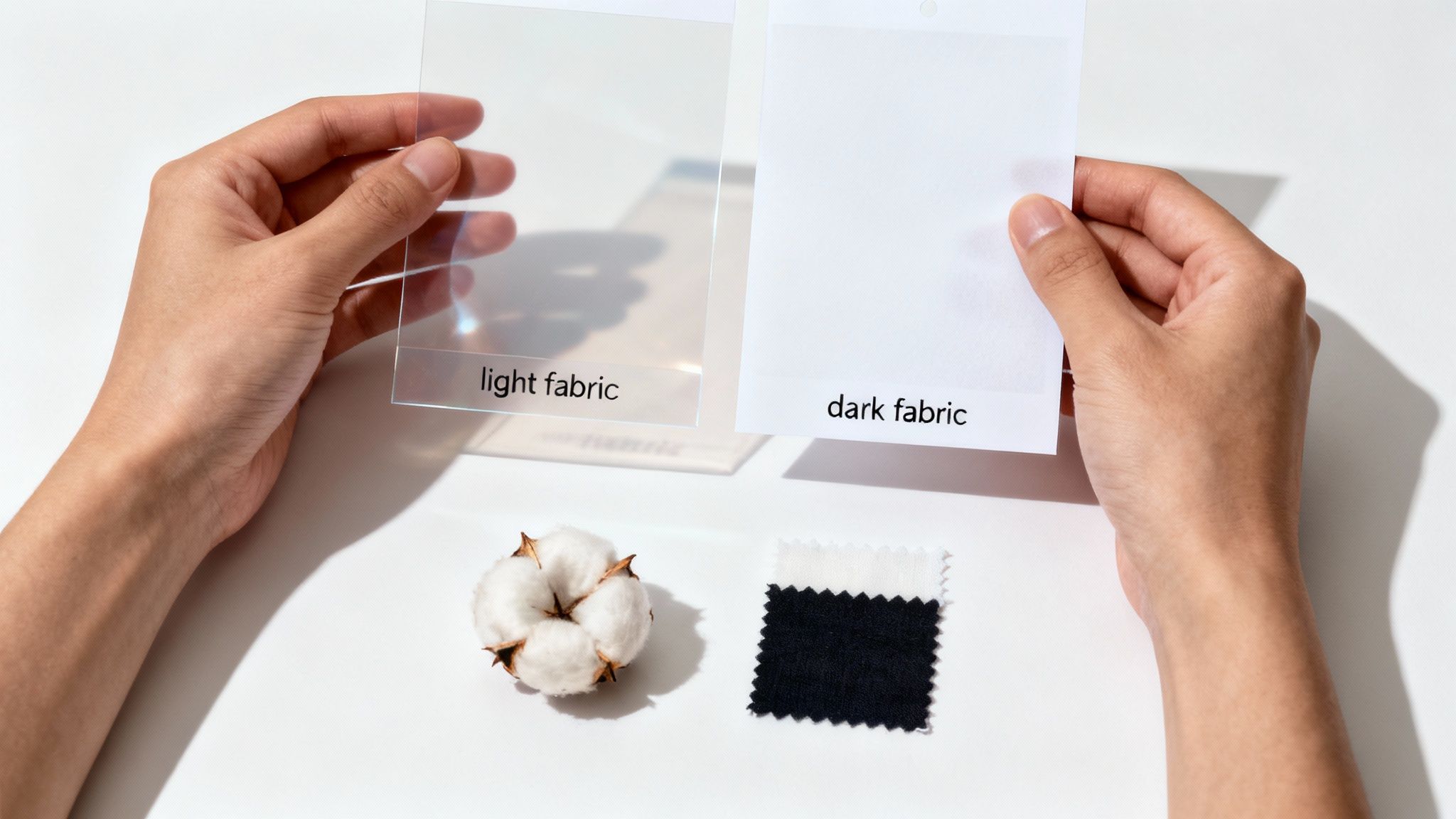

The first, and most critical, choice you need to make is between paper for light fabrics and paper for dark fabrics. They are not interchangeable, and believe me, getting this right from the get-go will save you a world of frustration.

Light vs Dark Fabric Paper: The Core Difference

Paper made for light-coloured garments (think white, beige, light grey, or pastels) uses a transparent polymer film. When you press the design, this clear film melts into the fabric, letting the shirt's light colour show through any unprinted parts of your image. This gives the design a softer feel, almost like it’s part of the material itself.

On the other hand, transfer paper for dark fabrics has a solid, opaque white background. This is crucial because if you printed directly onto a black, navy, or red shirt, the colours would look muddy or just disappear. The white layer acts like a primer on a dark wall, giving your ink a bright base so the colours pop exactly how you intended.

The single biggest mistake I see beginners make is using light transfer paper on a dark shirt. Because the film is clear, your design will just vanish into the dark material. At best, you might see a faint, ghostly outline, but you’ll definitely have a wasted shirt.

Understanding the options available helps, too. The iron-on transfer paper market in New Zealand is influenced by both local crafting trends and international suppliers. Global data shows that iron on print transfer paper is typically categorised by type (light vs. dark), finish (glitter, metallic), and its intended use (clothing, decor). This gives us Kiwi crafters a fantastic range of creative options. You can get a sense of how the global market is structured in this comprehensive market report.

To help you decide, here's a straightforward comparison of the two main types of transfer paper.

Light vs Dark Fabric Transfer Paper

| Feature | Light Fabric Paper | Dark Fabric Paper |

|---|---|---|

| Background | Transparent polymer film | Opaque white film |

| Best For | White, pastel, and light-coloured garments | Black, navy, red, and all dark or bright colours |

| Application | Image is printed in reverse (mirrored) | Image is printed as-is (not mirrored) |

| Feel | Softer, more integrated with the fabric | Slightly thicker, sits on top of the fabric |

| Trimming | Trim close, but transparent film is less visible | Must trim very precisely to avoid a white border |

Ultimately, the colour of your garment is the deciding factor. Always have both types on hand if you plan on doing a variety of projects.

Matching Paper to Your Fabric Material

Beyond just colour, the fabric's composition is a huge factor. Most standard iron-on papers are designed to work best with 100% cotton or 50/50 cotton/polyester blends. These fibres are great at handling the heat from an iron or heat press, which allows the transfer's adhesive to form a strong, lasting bond.

But what if you're working with something else? You’ll need to grab a specialty paper.

- For 100% Polyester or Activewear: Standard papers just won't cut it here; they often fail to stick properly or crack as soon as the fabric stretches. For activewear or sports jerseys, you need a paper specifically labelled as "stretchable" or "for synthetic fabrics." These have a more flexible polymer that moves with the material.

- For Canvas or Heavy Cotton: Things like tote bags and aprons are usually sturdy enough for standard paper. However, you'll likely need to increase your pressing time and apply more pressure to make sure the adhesive really sinks into those thick, coarse fibres.

Always, always check the packaging for the manufacturer’s recommendations on fabric compatibility. Following their specific instructions is the surest way to get a transfer that looks great and lasts.

Exploring Speciality Transfer Papers

Once you've nailed the basics of light and dark papers, you can start having some real fun. Speciality transfer sheets open up a whole new world of creative possibilities, adding a unique flair that you just can't get from a standard print.

Here are a few of the more popular options you might come across:

- Glitter Transfer Paper: This paper has a glittery base that makes your whole design sparkle. It’s a huge hit for kids' clothes, fun party t-shirts, or festive projects.

- Metallic Transfer Paper: Perfect for achieving a high-end, foil-like finish. You can find it in gold, silver, and rose gold, which adds a premium, reflective look to text and graphics.

- Glow-in-the-Dark Paper: A classic for a reason! This paper absorbs light and then glows when the lights go out. It's fantastic for novelty shirts, Halloween costumes, and kids' pyjamas.

- Flock Transfer Paper: If you want texture, this is the one to use. Flock paper creates a soft, fuzzy, almost suede-like feel. It’s brilliant for giving a retro vibe to lettering or for any design where you want a tactile, dimensional element.

Using these can really elevate your projects, turning a simple homemade item into something that looks professionally customised. Just remember that speciality papers often have their own unique instructions, so double-check the recommended pressing times and temperatures before you start.

Getting Your Design and Print Settings Just Right

This is where the magic really starts to happen—turning your digital idea into something you can actually hold. But before you even think about plugging in your iron or heat press, nailing your design file and print settings is absolutely crucial. Trust me, getting this part right is the single biggest factor in whether your project looks professional or like a disappointing mistake.

Think of it like building a house. Your digital file is the blueprint. If that blueprint is shaky or low-quality, it doesn't matter how well you do the final construction; the end result will always be flawed. Let's make sure your blueprint is perfect.

Prepping Your Design File

The quality of your finished transfer is a direct reflection of your source image. You simply can't take a tiny, pixelated picture you found online and expect it to transform into a sharp, vibrant print on a t-shirt. It just doesn't work that way.

The magic number you need to know is 300 DPI (Dots Per Inch). This is the standard resolution for high-quality printing. An image at 300 DPI has enough data packed into it to print cleanly without looking fuzzy or blocky. For comparison, most images you see on websites are only 72 DPI—great for a screen, but a blurry mess when printed onto iron on print transfer paper.

Here’s a rule I live by: if you have to stretch an image to make it fit, the quality is going to tank. Always, always start with the biggest, highest-resolution file you can possibly find.

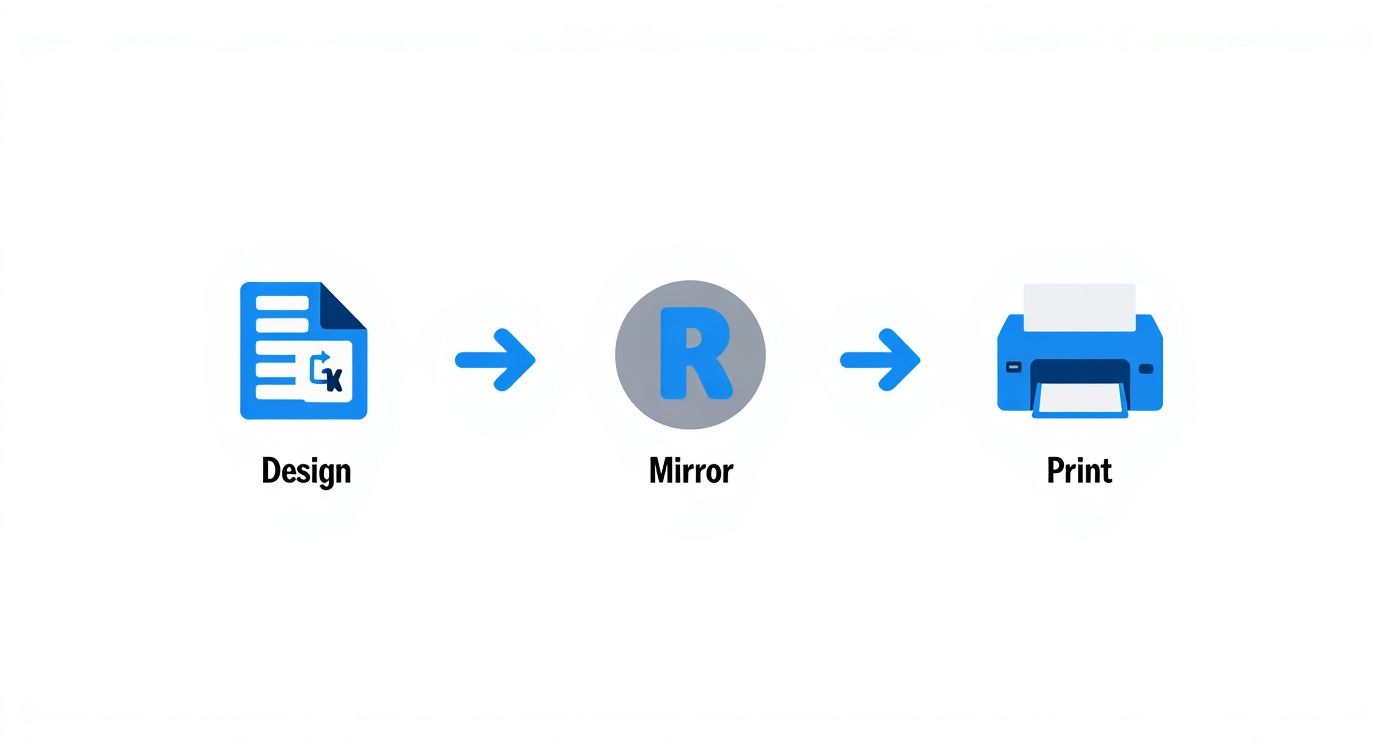

The All-Important 'Mirror Image' Step

Okay, listen up, because this is the one thing that trips everyone up at least once. Forgetting to mirror your design (or mirroring it when you shouldn't) is a classic rookie error, and the rule changes depending on your paper.

- For Light Fabric Paper: You MUST mirror your image. Think of it as creating a temporary tattoo. You're going to place the paper face-down on the fabric, so the image needs to be flipped horizontally to look correct once you press it and peel the backing off. If you don't, any text or logos will be backwards.

- For Dark Fabric Paper: You DO NOT mirror your image. This type of paper works differently. You peel the design off its backing first and then place it face-up on the shirt. What you see on your screen is exactly what you'll get. If you mirror it, you’ll end up with a backwards design.

Almost any design program, from Canva to Adobe Illustrator, has a "flip horizontal" or "mirror" option. Your printer's settings dialogue probably has one too. Just take a moment to double-check you've chosen the right setting for your specific paper before you hit that print button.

Dialling in Your Printer Settings

Your home printer is a pretty clever piece of kit, but its default settings are usually geared for printing boring text documents, not creating brilliant, full-colour transfers. To get the rich, vibrant result you’re after, you need to give it a few specific instructions.

When the print dialogue box pops up, don't just reflexively click "Print." Take 30 seconds to find and adjust these settings for your iron on print transfer paper:

-

Paper Type: Dive into the paper or media type settings. You probably won't find an option that says "Iron-On Transfer," and that's fine. Instead, look for choices like "Photo Paper Matte," "Premium Matte Paper," or maybe even "T-Shirt Transfer." Choosing a photo paper setting tells your printer to expect a thicker sheet and to lay down more ink for better colour.

-

Print Quality: This is a big one. Change the quality from "Standard" or "Normal" to "Best," "High," or "Fine." Yes, it will print a bit slower, but it makes a world of difference. This setting forces the printer to be more precise, ensuring you get the sharpest lines and the most saturated colours possible.

-

Colour Management: If you see an advanced option for colour, make sure it’s set to "Printer Manages Colours" or something similar. This helps align what you see on your backlit screen with what the printer's ink can actually produce on paper.

These small tweaks take less than a minute but have a massive impact on your final project. It's the difference between a design that looks a bit washed-out and one that has real punch and professional clarity. Getting this print stage right sets you up perfectly for a flawless transfer.

Mastering the Heat Application Process

Alright, this is the moment of truth—where your digital design becomes a real-deal custom print. Getting this part right comes down to precision and a bit of patience, but the payoff is huge. The two main tools for the job are a standard household iron or a dedicated heat press. Both can deliver fantastic results, but they each have their own quirks and techniques.

You absolutely don't need fancy equipment to get started. A good old iron can work wonders, as long as you know how to work around its limitations. But if you get bitten by the customisation bug and start making things regularly, a heat press is a game-changer for getting consistent, professional-looking results every time. Let's break down both methods.

Before we dive in, this infographic recaps the crucial prep work we've already covered. Getting these steps right is non-negotiable for a good final press.

As you can see, it all starts with a high-resolution design, which is then mirrored correctly for your paper type and printed with the right settings. Nail these, and you're ready for the main event.

Using a Household Iron for Great Results

An iron is obviously the most accessible tool, but its biggest weakness is inconsistency. The trick is to control every variable you can. First up, your surface.

Do not use a standard ironing board. They’re built to be soft and to dissipate heat, which is the exact opposite of what you need for a successful transfer. Instead, find a solid, heat-resistant surface like a wooden dining table or a kitchen benchtop. Just be sure to protect it by laying down a cotton pillowcase or a Teflon sheet first.

Next, you'll need to get your iron's settings dialled in perfectly.

- Temperature: Crank it up to the highest setting. This is usually labelled 'Cotton' or shown as three dots on the dial.

- Steam: This is critical. Make absolutely sure the steam function is OFF and the water tank is empty. Any moisture will completely ruin the adhesive.

- Preheat: Let the iron get properly hot. Give it a good five minutes to reach its maximum temperature before you even think about pressing.

Once you’re ready, place your trimmed design onto the pre-ironed garment. The key from here is applying firm, consistent pressure. I mean it—really lean into it. This isn't like ironing out wrinkles where you glide the iron around. You need to press down hard with your body weight, holding the iron still for 15-20 seconds before lifting it and moving to the next overlapping section. Make sure every single part of the design gets this treatment, paying special attention to the edges.

The Heat Press Advantage for Consistency

If you're planning on making more than just a few one-off projects, a heat press is an investment you won't regret. It takes all the guesswork out of the equation by delivering perfectly even heat and pressure, something an iron just can't do. It’s the closest you’ll get to professional quality at home.

Setting up a heat press is surprisingly simple. You just need to set three things according to your iron on print transfer paper instructions:

- Temperature: Usually somewhere between 160°C and 180°C.

- Time: Typically anywhere from 10 to 30 seconds.

- Pressure: Most papers call for medium or firm pressure.

That precision ensures the adhesive melts perfectly into the fabric’s fibres across the whole design. The result is a far more durable transfer that holds up beautifully in the wash. This concept of bonding materials with heat is common in fabric crafts; for more on the topic, you can explore fusible interfacing techniques, which work on similar principles of adhesion.

Hot Peel vs. Cold Peel: The Final Step

After the heat has been applied, the very last step is to remove the backing paper. But when and how you do this is absolutely vital. Transfer papers are either ‘hot peel’ or ‘cold peel’, and mixing them up can ruin all your hard work.

Always, always check the instructions that came with your iron on print transfer paper. This is not the time to guess. Peeling a hot peel paper when it's cold can lift the design right off, while peeling a cold peel paper too early can cause the ink to smear.

So, what's the difference?

-

Hot Peel: Just like it sounds, you peel the backing paper off almost immediately after pressing, while everything is still piping hot. This tends to give the design a softer, more matte finish as it sinks right into the fabric. Just be careful with your fingers!

-

Cold Peel: With this type, you have to exercise some patience. Let the transfer cool down completely to room temperature before you even think about touching the backing paper. It might take a few minutes. Cold peel transfers often have a slightly glossier, smoother finish, as the film sits more on top of the fabric.

When you do peel, pull the backing paper away smoothly at a low, consistent angle. If you see any part of the design starting to lift with the paper, stop right away. Lay the backing paper back down, cover it with a sheet of parchment paper, and press it again for another 10-15 seconds. That extra bit of heat and time almost always solves the issue.

Keeping Your Creations Looking Great: Long-Term Care and Troubleshooting

https://www.youtube.com/embed/sxyJrOMqOs0

So, you’ve put in the work and made something awesome. The next challenge is making sure that design looks just as sharp after a dozen washes as it did the moment you peeled back the paper. Honestly, the aftercare is just as critical as the application itself—it’s the difference between a one-wash wonder and a t-shirt that lasts for years.

A few simple habits will go a long way in extending the life of your custom gear. It all comes down to being gentle with the transfer to protect that adhesive bond you worked so hard to create.

Washing and Drying Like a Pro

That first wash is the make-or-break moment. You absolutely must wait at least 24 hours after pressing before your garment sees the inside of a washing machine. This gives the transfer’s adhesive the time it needs to fully cure and grip the fabric fibres for good.

When laundry day rolls around, stick to these rules religiously:

- Turn It Inside Out: This is non-negotiable. It’s the single best thing you can do to shield your iron on print transfer paper design from getting scuffed up by other clothes, zips, and buttons.

- Go Cold and Gentle: Hot water is the enemy. It can soften the adhesive, leading to peeling and cracking down the line. Always opt for a cold wash on a gentle or delicate cycle to keep the stress on the design to a minimum.

- Use a Mild Detergent: Stay away from harsh detergents, bleach, and especially fabric softeners. These can slowly eat away at the ink and the polymer film, causing the colours to fade way too soon.

Drying is just as important as washing. The high, direct heat from a typical clothes dryer can absolutely destroy a custom transfer.

The best method, hands down, is to hang the garment to dry. Air drying costs nothing, eliminates any risk of heat damage, and is the kindest way to preserve the colour and feel of your design.

If you’re in a pinch and have to use a machine, choose the lowest heat setting available—think 'tumble dry low' or an air-only cycle. Pull the garment out while it’s still a tiny bit damp and let it finish air drying. And whatever you do, never iron directly on top of a finished transfer. If the shirt needs ironing, turn it inside out and use a low heat setting, carefully avoiding the design area.

Fixing Common Problems

Even the most seasoned crafters run into issues sometimes. Don’t worry—most hiccups with iron on print transfer paper are pretty common and surprisingly easy to fix once you know what to look for.

Here’s a breakdown of the usual suspects and how to sort them out.

Problem 1: The Design Is Lifting or Not Sticking

You start to peel the backing paper, and to your horror, parts of the design are still stuck to it or are lifting off the fabric. This is almost always a classic heat and pressure problem.

- What Went Wrong: The culprit is usually not enough heat, not enough pressure, or both. A standard household iron is famous for having cool spots, and it’s easy to misjudge just how much body weight you need to lean into it.

- How to Fix It: If you haven’t removed the backing paper completely, lay it back down. Place a sheet of parchment paper over it and repress the stubborn spot for another 15-20 seconds. This time, apply serious pressure. Remember, you need a hard, flat surface for this—an ironing board is too soft and will absorb all your effort.

Problem 2: The Colours Look Washed Out After Pressing

The image looked fantastic on the paper, but now on the shirt, it just looks dull and faded.

- What Went Wrong: You probably just used your printer's default settings. Those 'standard' or 'normal' modes are designed to conserve ink, which is the exact opposite of what you need for a punchy, vibrant transfer.

- How to Fix It: Unfortunately, this can't be fixed after the fact, but it's an easy fix for next time. Before you print, dive into your printer’s settings. Change the print quality to 'Best' or 'High' and tell it you’re using 'Matte Photo Paper' or a similar heavy paper type. This signals the printer to lay down more ink, giving you much richer colours that will hold up.

Problem 3: The Design Is Cracking or Peeling After a Wash

The shirt looked perfect right after you made it, but the design started cracking or flaking after its first trip through the laundry.

- What Went Wrong: This is a sign of an improper cure. The issue could be that the initial press time was too short, the pressure wasn't firm or even enough, or you washed the garment before that crucial 24-hour waiting period was up.

- How to Fix It: This one is all about prevention. Double-check the recommended time and temperature settings for your specific transfer paper and follow them to the letter. Apply firm, consistent pressure during application. Most importantly, be patient and let the shirt sit for a full 24 hours before that first wash to give the adhesive a fighting chance.

Got Questions About Transfer Paper? Let's Get Them Answered

Even with a perfect tutorial, diving into a new craft material always brings up a few questions. It’s completely normal. Here, I'll walk you through some of the most common head-scratchers people have when working with iron-on print transfer paper, so you can get your project done right.

Can I Use My Laser Printer for This?

This is a big one, and it's where a lot of people get stuck. The quick answer? Almost certainly not. The transfer paper you’ll find on the shelves at your local craft shop is almost always designed specifically for inkjet printers.

Trying to run inkjet paper through a laser printer is a recipe for a very expensive mess. Laser printers get incredibly hot to fuse toner to the page, and that heat will melt the transfer paper’s coating right onto the internal parts of your machine. Trust me, it’s a nightmare to clean and can cause serious damage. While you can find specialty papers for laser printers, they are less common, so always double-check the packaging to be sure it explicitly says "for laser printers".

Always, always, always check that your paper is compatible with your printer. That one quick glance at the box can save you a huge repair bill and a whole lot of frustration.

Why Does My Design Feel So Stiff and Plasticky?

That stiff, almost plastic-like feeling is a really common issue, especially for beginners. You'll notice it most with transfer papers made for dark fabrics.

The reason is simple: paper for darks has a solid white, opaque layer. This layer sits on top of the fabric so your colours show up bright and vibrant, but it also adds thickness. The good news is, you can definitely minimise it.

- Trim Like You Mean It: This is the best trick in the book. Before you press the design, get in there with sharp scissors or a craft knife and trim away every last bit of unprinted white space. The less excess material you press, the less stiffness you’ll feel.

- Find Softer Papers: Keep an eye out for newer brands marketing "soft-feel" or "stretchable" transfer papers. They have a much lighter feel on the shirt and are a lot more flexible.

- Watch the Heat: If you're working with transfers for light fabrics and still getting a stiff result, you might be using too much heat. Over-baking the polymer film makes it rigid. Stick to the recommended time and temperature settings for a much softer finish.

How Long Until I Can Wash My Awesome New Shirt?

I get it – you’ve just made an amazing custom shirt and you want to wear it right now! But this is where a little patience makes all the difference for how long your design will last.

You absolutely need to wait at least 24 to 48 hours after pressing before you even think about putting it in the wash. This waiting period is non-negotiable. It gives the transfer's adhesive time to fully cure and properly bond with the fibres of the fabric.

If you wash it too soon, you shock that bond while it's still setting up. This is the number one reason designs crack, peel, or fade after just one or two trips through the laundry. Giving it that day or two to rest is the single most important thing you can do to protect your hard work.

Here at SONI DESIGN, our passion is helping you turn creative ideas into reality with top-notch materials and real-world advice. Whether you're making one t-shirt for a laugh or outfitting an entire team, we've got the tools and know-how to make your project a huge success. Come and explore our range of design and print solutions today

Leave a Comment

Stay home & get your daily

needs from our shop

Start You'r Daily Shopping with Nest Mart

Best prices & offers

Orders $50 or more

Free delivery

24/7 amazing services

Great daily deal

When you sign up

Wide assortment

Mega Discounts

Easy returns

Within 30 days