Your cart is currently empty.

Ever wonder what that lightweight, rigid board is that you see everywhere from trade shows in Auckland to café menus in Wellington? Chances are, it's foam core board.

Think of it as a high-performance sandwich. You've got a core of lightweight polystyrene foam squished neatly between two smooth, sturdy paper liners. It's this simple construction that makes it one of the most versatile materials for signs and displays across New Zealand.

What Is Foam Core Board and Why Use It?

At its heart, foam core is all about getting maximum visual impact with minimum weight. The inner polystyrene is mostly trapped air, which is what makes the board incredibly light and easy to handle.

This is a huge plus. Imagine trying to set up a big display for a property viewing in Queenstown. With foam core, one person can easily carry and position signs that, if made from wood or metal, would be a major logistical headache.

A Balance of Rigidity and Portability

But don't let its light weight fool you. Foam core board is surprisingly rigid.

Those two outer paper layers aren't just for looks; they provide tension and stability, stopping the foam centre from bending or warping. This is what keeps your signs, architectural models, or presentation boards looking sharp and professional, not flimsy and cheap.

This unique mix of features makes it a go-to for so many Kiwi businesses. The main benefits really come down to:

- Exceptional Portability: Perfect for events and mobile displays where you need to get in and out quickly.

- Professional Finish: The ultra-smooth surface is a brilliant canvas for printing, giving you crisp text and vibrant images every time.

- Cost-Effective: It delivers a premium look without the hefty price tag you’d get with materials like PVC or aluminium.

Foam core board hits that perfect sweet spot between performance and practicality. It gives you the visual punch of a much heavier material, but with the convenience and affordability that New Zealand businesses really need.

Ultimately, if you need a solution that looks fantastic, is a breeze to handle, and won't blow the budget, foam core is almost always the answer. It perfectly bridges the gap between a basic paper poster and more expensive, permanent signage.

Choosing the Right Foam Board for Your Project

Picking the right foam core board is a bit like choosing the right tool for a job. They might all look similar at first glance, but the small differences in thickness and finish can make or break your project. In New Zealand, you’ll typically run into three standard thicknesses, and each one has its own sweet spot.

Getting this choice right means your project will have the strength and visual punch it needs, without you paying for features you don't. It's all about matching the board to what you’re trying to achieve—whether that's a small photo print for your home or a massive, freestanding display for an event at the Viaduct Events Centre.

Decoding Foam Board Thickness

The thickness of a foam core board is what gives it rigidity and durability. It’s pretty straightforward: thicker boards are stronger and less likely to bend, which makes them the go-to for bigger signs or more demanding jobs.

Here’s a quick rundown of the common options for foam core board in NZ:

-

3mm: This is your slimmest and lightest option. Its real strength is its subtlety—it’s perfect for mounting high-quality photos or prints where the artwork, not the backing, should be the hero. You'll want to use this for smaller pieces that are either going into a frame or being stuck flat against a wall.

-

5mm: The all-rounder and by far the most popular choice. 5mm board hits that sweet spot between being rigid enough for most tasks but still lightweight and easy to handle. It's sturdy enough for things like A1 event signage, presentation boards, and retail displays. If you’re not sure what to get, 5mm is usually a safe bet.

-

10mm: When you need a board that absolutely won’t flex, 10mm is what you’re looking for. This is the heavyweight champion, ideal for big, freestanding displays, detailed architectural models, or large signs that need to stay perfectly flat. Its thickness gives it a real presence, perfect for making an impact at a trade show or in a shop entryway.

To make it even simpler, here's a quick guide to help you decide.

Foam Core Board Thickness Guide

A quick reference to help you choose the right foam board thickness for your application in New Zealand.

| Thickness | Common NZ Applications | Key Benefit |

|---|---|---|

| 3mm | Photo mounting, small framed prints, craft projects. | Lightweight and subtle. |

| 5mm | Event signage, presentation boards, retail displays. | Versatile and cost-effective. |

| 10mm | Freestanding displays, large-scale signage, architectural models. | Maximum rigidity and stability. |

Ultimately, thinking about how your sign will be used and where it will be displayed will point you to the perfect thickness every time.

Choosing Your Board Finish

Thickness is only half the story; the surface finish is just as important. The right finish can make your job a lot easier and give your project that professional look.

The standard paper-faced boards you see everywhere have a smooth, matte white surface that's great for printing on directly or mounting prints to. But if you want to save yourself a bit of hassle, a self-adhesive foam board is a brilliant shortcut. These boards have a sticky side covered by a peel-away liner, letting you mount your prints perfectly without any messy glues or sprays.

And a quick pro tip: no matter what board you're working with, a good quality cutting mat for precise cuts is a non-negotiable for getting clean, sharp edges and protecting your tabletop.

By carefully considering both the thickness and the finish, you can select a foam core board that not only supports your design but actively enhances it, ensuring a professional and durable result for any project.

How We Get Your Designs onto Foam Board

This is where your digital file becomes a real-world display. Getting your design onto a foam board isn't a one-size-fits-all job. Here in NZ, we generally use two main techniques, and picking the right one comes down to what you need your sign to do—whether it’s about durability, visual impact, or fitting a specific budget.

Knowing the difference helps you make a smarter call. It’s the key to making sure your final piece doesn't just look great on day one, but is also built for its environment, be it a one-day conference or a permanent fixture in your office.

Direct to Board UV Printing

Think of this as the high-tech, modern approach. We use a massive flatbed printer that works a bit like your office inkjet, but instead of printing on paper, it prints straight onto the foam board itself.

The printer lays down a special UV ink, and a powerful ultraviolet light follows right behind, instantly hardening—or "curing"—the ink. This creates a tough, slightly textured finish that’s bonded directly to the board. It's incredibly efficient and results in vibrant colours with a subtle semi-matte look. Best of all, because the ink becomes part of the board, it won’t peel, bubble, or fade easily.

The Mounting Method

The other way to do it is a more traditional two-step process called mounting. It’s a classic for a reason. First, we print your design onto a separate sheet of high-quality material, like a premium photo paper or a tough adhesive vinyl.

Then, that print is meticulously applied to the foam board by our team. We ensure it goes on perfectly smooth, with no bubbles or wrinkles. This method is brilliant when you're after a specific look, like the high-gloss sheen of a professional photograph, because the final texture is determined by the paper we print on.

Choosing between direct printing and mounting often comes down to balancing longevity with visual finish. Direct UV printing offers superior durability for high-traffic areas, while mounting provides a wider range of textural finishes for more artistic applications.

Adding the Finishing Touches to Elevate Your Design

The printing is just step one. To give your foam core board nz project that professional edge and make it last, we can add some finishing touches. These final steps are what protect your print and give it that extra "wow" factor.

Two of the most popular options are:

- Lamination: We apply a thin, protective film over the entire print. A matte laminate is perfect for cutting down glare and hiding fingerprints—great for gallery displays or presentation boards. A gloss laminate, on the other hand, makes colours seriously pop and gives a reflective shine that’s fantastic for promotional signs that need to grab attention.

- Custom Shape Cutting: Who says signs have to be rectangular? With our precision digital cutters, we can cut your board into almost any shape you can dream up. Think about a sign shaped like your company logo, a product, or even giant lettering. It instantly transforms a simple board into a bespoke piece that people can't ignore.

By pairing the right printing method with the perfect finish, you get a piece that truly stands out. Whether it’s the rugged, modern finish of direct UV printing or the custom look of a mounted and laminated board, you have complete control over the final product.

Getting the Size Right: Common Foam Board Dimensions in NZ

Choosing the right size for your foam board project is more than just a minor detail—it has a massive impact on everything from visual appeal to your final budget. Here in New Zealand, we stick to standard international paper dimensions, which is great news because it makes planning your designs a whole lot easier.

When you know the standard sheet sizes, you can design your artwork to fit perfectly. This means less off-cutting, less material waste, and ultimately, a better price for your project. Whether it's a small A4 sign for a retail counter or a huge backdrop for a trade show, getting the dimensions right from the very beginning is the key to a stress-free process.

The A-Series: Your Everyday Standard

Chances are, the size you need will fall into the A-series. This is the system most of us are familiar with. It's built on a simple, logical scale: an A3 is made of two A4s, an A2 is made of two A3s, and so on. This makes it incredibly easy to scale your designs up or down without any awkward resizing.

These sizes cover the vast majority of business needs. An A1 board, for example, is the go-to for wedding welcome signs and event seating charts. Stepping down, an A3 or A4 board is perfect for things like café menus, point-of-sale displays, or presentation boards that need to be propped up on a desk.

Standard Foam Core Board Sizes in NZ

To give you a clearer picture, here’s a quick rundown of the standard foam board sizes you'll find across New Zealand. Thinking about where your sign will end up and what it needs to do will help you lock in the perfect choice.

| Size Name | Dimensions (mm) | Typical NZ Use Case |

|---|---|---|

| A4 | 210 x 297 mm | Countertop signs, small posters, photo prints, and handouts. |

| A3 | 297 x 420 mm | Café menus, detailed charts, small directional signs. |

| A2 | 420 x 594 mm | Retail sale signs, presentation boards, window displays. |

| A1 | 594 x 841 mm | Event welcome signs, conference visuals, architectural plans. |

| Large Format | Up to 1220 x 2440 mm | Large-scale trade show backdrops, custom-cut displays. |

Thinking in these standard sizes from the start just makes everything run smoother. It simplifies the design phase, the printing setup, and even shipping, saving you from headaches and unexpected costs down the line.

By selecting a standard size from the outset, you streamline the entire process. It simplifies design, printing, and even shipping, ensuring your project runs smoothly from concept to completion without any costly surprises.

Of course, sometimes you need to go big. Beyond the A-series, professional printers like us at Soni Design regularly work with full-size sheets, typically measuring a massive 1220 x 2440 mm. These are the workhorses for large, custom projects where you need a seamless, professional finish without any distracting joins.

Foam Core Board Compared to Other Materials

Choosing the right material for your project is everything. While foam core is a fantastic choice for indoor displays, it’s good to know how it stacks up against other popular sign materials here in New Zealand. This will help you make sure you’re getting the perfect fit for your needs.

Every material has its own strengths, a bit like picking the right tool for a job. You wouldn't use a hammer to drive a screw, and you definitely wouldn't put an indoor-only sign out in the middle of a Wellington southerly. Let’s break down when foam core is the star of the show and when another option might be a better bet.

Corflute: The Outdoor Specialist

If your sign needs to brave the elements, Corflute is your go-to. Made from corrugated plastic, it’s basically the plastic version of cardboard—lightweight, weather-resistant, and really cost-effective for short-term outdoor use.

Think of those real estate signs you see on lawns all over NZ; that’s Corflute doing its job. It's tough enough for the outdoors, but its slightly ribbed surface means it can't quite match the perfectly smooth, high-resolution finish you get with foam core board in NZ. For temporary outdoor signs, Corflute is the winner. For premium indoor quality, foam core comes out on top.

PVC Board: The Durable All-Rounder

When you need something a bit tougher than foam core but still want a high-quality look for indoor displays, PVC foam board is an excellent choice. It's a solid, dense plastic that’s far more resistant to knocks, dents, and moisture than standard foam core.

Of course, that extra durability comes with a higher price tag and a lot more weight. PVC is brilliant for long-term retail signage or displays in busy areas where they might get bumped around. But for presentations, mounted photos, or lightweight event signs, foam core's easy portability and lower cost make it the more practical option.

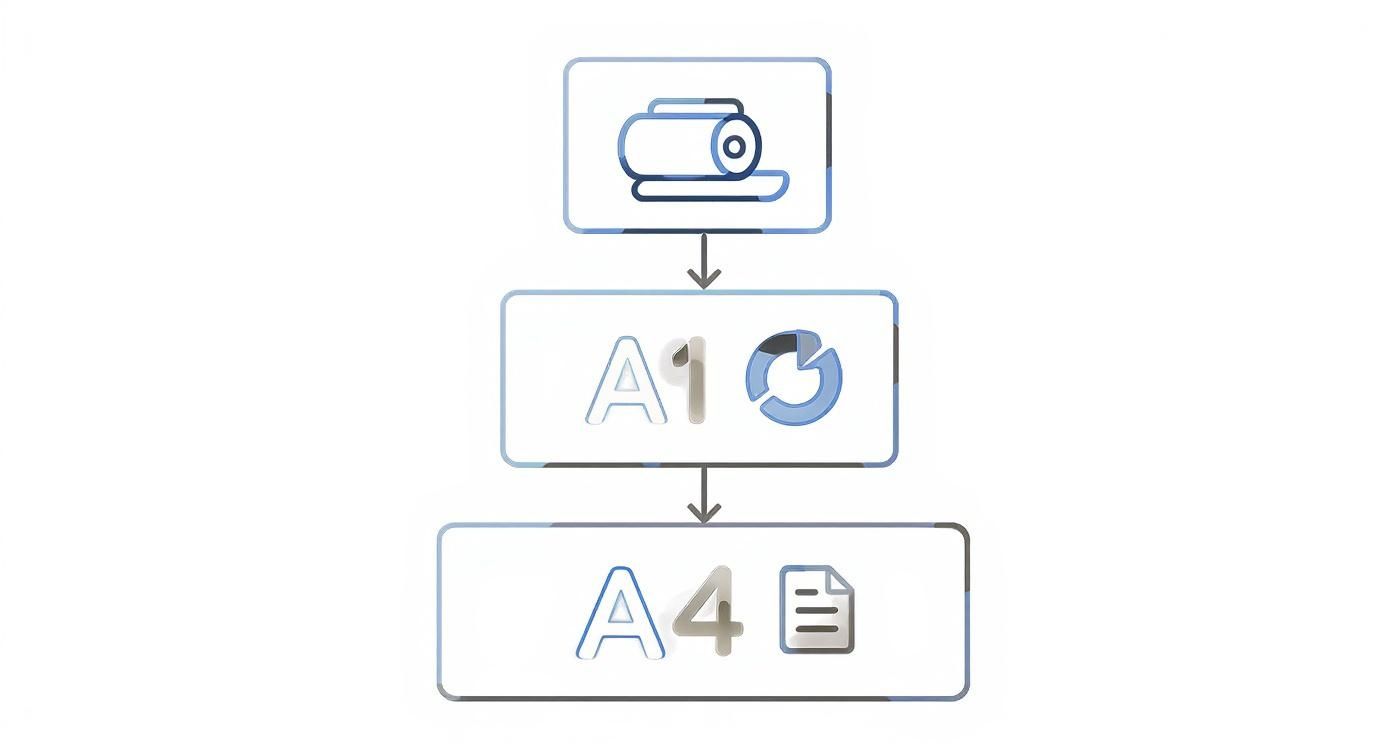

The diagram below gives you an idea of the typical workflow, from large-format source material down to common finished sizes.

This shows how we can work with large print rolls to create custom jobs like A1 signs, right down to standard A4 displays for smaller applications.

Aluminium Composite Material: The Premium Choice

For the ultimate in durability and a sleek, modern look, there's Aluminium Composite Material (ACM). This is made of a plastic core sandwiched between two thin sheets of aluminium. ACM is incredibly rigid, completely weatherproof, and has a very professional, high-end appearance.

For projects demanding the highest level of durability and a sophisticated finish, such as permanent architectural signage or high-end outdoor business signs, ACM is the undisputed leader. It's an investment in permanence where foam core offers temporary brilliance.

ACM is the most expensive and heaviest of these options, hands down. It’s the perfect choice for permanent outdoor building signage or premium interior displays where budget isn’t the main concern. By comparison, foam core board delivers a lightweight, affordable solution for projects that need brilliant visuals without requiring extreme durability or weather resistance.

A Look Inside New Zealand’s Foam Product Market

When you grab a sheet of foam core board in NZ, you're getting more than just a piece of signage. You're actually tapping into a surprisingly large and experienced local industry.

The same core technology that makes your display board light yet rigid is also used across New Zealand's bustling construction sector, particularly for high-performance insulation panels. This is a great indicator of its quality. After all, if the material is trusted to insulate Kiwi homes and provide structural integrity, you can be confident it's built on solid engineering principles.

A Strong Local Industry

The fact that we have a well-established local market for foam-based products is fantastic news for anyone buying them. A competitive scene pushes manufacturers to innovate, keeps quality high, and means the supply chain for materials like foam core board is incredibly reliable.

By choosing a locally available foam core product, you’re getting something backed by an industry that’s always improving. It’s a dependable material supported by a solid network of local know-how.

This strong local presence means you get a product that has been proven time and again in some seriously demanding fields. As of 2023, there were roughly 66 businesses in New Zealand's wider foam manufacturing sector. That’s a solid footprint.

This industry backbone, largely focused on polystyrene foam, ensures the foam core board nz you buy is a cost-effective, tough, and reliable solution for your project. You can dive deeper into the local market dynamics in the Commerce Commission's 2023 determination report.

At the end of the day, this context matters. It shows that your foam core board isn't just a standalone product; it’s supported by a significant local industry known for producing versatile materials for everything from nationwide building projects to intricate creative displays.

Got Questions About Foam Core Board? We've Got Answers.

When you're getting ready to kick off a new project, a few practical questions about foam core board always seem to surface. It’s completely normal. Getting these details sorted upfront means you'll pick the right material for the job and know exactly how to care for it, avoiding any headaches later on.

We've pulled together the top questions we hear from our customers all over New Zealand to help you get started with confidence.

Is Foam Core Board Waterproof?

In a word, no. A standard foam core board has paper facings, and just like any paper, it will soak up moisture. If it gets wet, it’s going to warp, bubble, and lose all its rigidity. Think of it as a strictly indoor-only display solution.

If your sign needs to brave the often-unpredictable Kiwi weather, you’ll be much better off with something built for the outdoors, like Corflute or a solid PVC board. They’re designed to shrug off rain and humidity without a problem.

Sure, you might get away with using it for a one-day event if you're promised a perfect, sunny afternoon, but it's a gamble.

Key Takeaway: Foam core board is not waterproof and belongs indoors. For any outdoor signage in New Zealand, materials like Corflute or PVC board are the way to go for durability and peace of mind.

How Should I Clean My Board?

Keeping your board looking sharp is easy. For everyday dust, a quick, gentle wipe with a dry microfibre cloth is all it takes. If you spot a small smudge, just dampen a tiny corner of the cloth with a little water and carefully dab the mark.

The main thing to avoid is harsh chemical cleaners or getting the board too wet. Too much moisture can easily damage the paper surface and compromise the print. A little bit of care goes a long way in keeping your display looking great.

Can Foam Core Board Be Recycled in NZ?

This is where it gets a bit complicated. Technically, the inner polystyrene foam and the outer paper layers are recyclable materials on their own. The problem is that they're bonded together to create the board.

Most local council recycling programmes here in New Zealand don't have the facilities to separate these fused materials. This means that, in almost all cases, foam core board cannot be tossed into your kerbside recycling bin.

It's always a good idea to double-check the specific guidelines with your local council, but you'll likely find it needs to go into the general waste.

Ready to bring your vision to life with the perfect indoor display? The team at Soni Design is here to help you choose, design, and print stunning foam core board signs for your business. Explore our custom printing services today!

Leave a Comment

Stay home & get your daily

needs from our shop

Start You'r Daily Shopping with Nest Mart

Best prices & offers

Orders $50 or more

Free delivery

24/7 amazing services

Great daily deal

When you sign up

Wide assortment

Mega Discounts

Easy returns

Within 30 days