Your cart is currently empty.

When it comes to digital printing vs offset printing, your decision really boils down to three things: the volume you need, how quickly you need it, and your budget. In a nutshell, digital printing is your go-to for speed and affordability on smaller jobs. On the other hand, offset printing delivers unbeatable quality and a lower price per piece when you're printing in bulk.

Choosing Your Best Printing Method

Picking the right printing method isn't just a technical choice; it's a business decision that directly affects your project's final cost, quality, and deadline. For any Kiwi business, getting to grips with the fundamental differences is the first step. It ensures you get the results you want, whether you're rushing to print event flyers or producing a high-volume product catalogue.

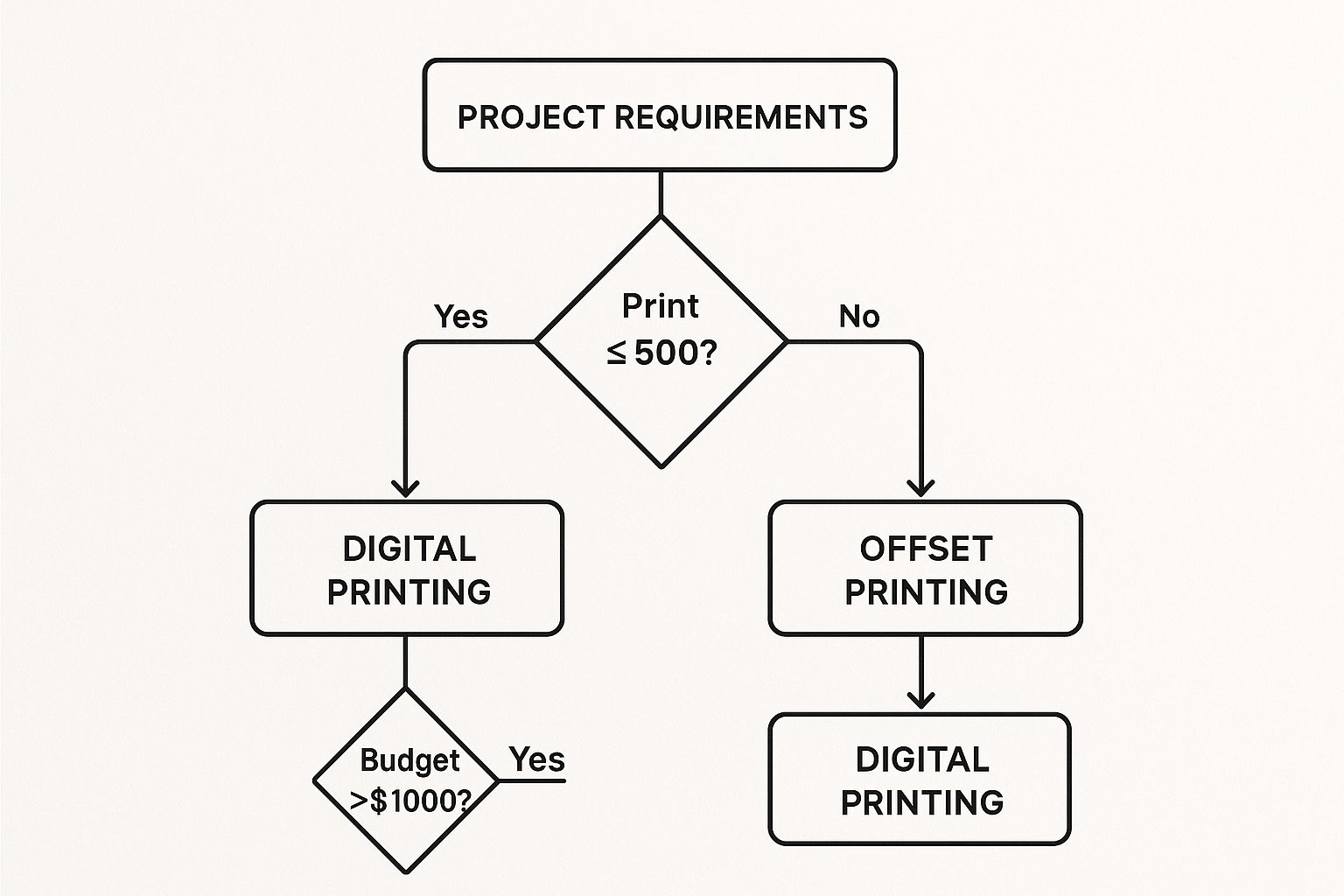

This decision tree clearly lays out how the size of your print run and your budget are the main things to think about when choosing between digital and offset.

As the graphic shows, if your project involves a print run of less than 500 units, digital printing is almost always the smarter, more economical choice.

Key Decision Factors

Your final choice will come down to a balance of these key elements. It's a classic trade-off between the upfront setup cost, the final price per item, and how fast you can get the finished product in your hands.

- Project Volume: How many copies do you actually need? This is usually the first and most important question to answer.

- Turnaround Time: Is this an urgent job for tomorrow, or can it wait until next month?

- Budget: Are you more focused on the total invoice amount or the cost-per-unit for a large run?

- Quality & Materials: Does your design demand precise brand colour matching or a special type of paper stock?

The guiding principle is straightforward: Digital printing is built for speed and flexibility on smaller jobs. Offset printing truly shines with volume, offering significant cost savings and premium quality for large-scale projects.

It's also worth thinking about how modern business models use these technologies. For instance, e-commerce businesses often rely on print-on-demand platforms like Printify, which are powered by digital printing to produce items only when an order is placed, eliminating inventory costs.

Quick Comparison: Digital vs Offset Printing

To help you see the differences at a glance, here’s a quick table that breaks down the main attributes of each method. Use it as a starting point to figure out which direction to go in.

| Attribute | Digital Printing | Offset Printing |

|---|---|---|

| Best For | Short runs (under 500) | Long runs (500+) |

| Turnaround | Fast (hours to a few days) | Slower (several days to weeks) |

| Setup Cost | Very low to none | High (due to plate creation) |

| Cost-Per-Unit | Higher for large volumes | Lower for large volumes |

| Customisation | Excellent (variable data) | Not possible per print |

This table makes it clear that there's no single "best" method—the right choice depends entirely on your project's specific needs.

How Each Printing Process Actually Works

Before you can really weigh up digital versus offset printing, it helps to get a picture of what’s happening behind the scenes. The two methods are fundamentally different, and it's these technical differences that dictate everything from cost and speed to the quality of the final product.

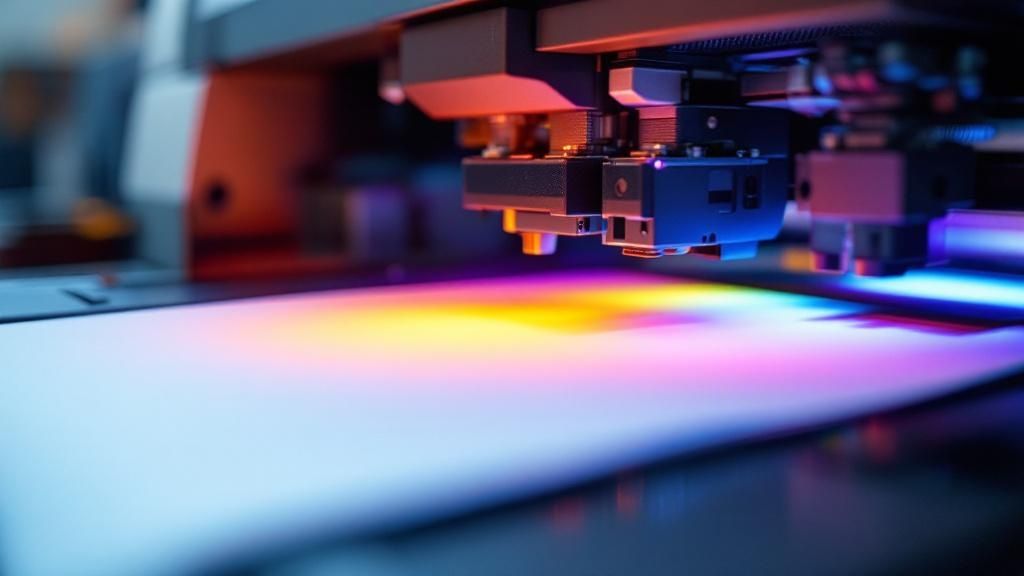

Think of digital printing as a souped-up version of the printer sitting in your office, just built for commercial-grade work. It takes a digital file, like a PDF, and prints it straight onto the paper or whatever material you're using.

There are no plates, no complex setup. The printer simply uses liquid ink or powdered toner to recreate your design directly on the surface. This streamlined process is precisely why it’s so quick and efficient for smaller jobs.

The Offset Printing Method Explained

Offset printing, also known as lithography, is a far more mechanical affair. It’s a classic, multi-step process built on a surprisingly simple principle: oil and water don't mix. Your design has to go on quite a journey before the ink ever hits the paper.

It all starts with creating custom metal plates, typically made of aluminium, for each colour in your design. For a standard full-colour job, this means making four separate plates: Cyan, Magenta, Yellow, and Key (black) — what we call CMYK.

Here’s a quick rundown of how the ink gets transferred:

- Your design is chemically etched onto the metal plates.

- Ink is applied to the plates and only sticks to the etched image areas.

- The inked image is then transferred (or "offset") from the plate to a soft rubber blanket.

- Finally, this rubber blanket rolls the image onto the paper, delivering a crisp, professional finish.

That indirect transfer—from plate to blanket to paper—is what gives offset printing its name and its renowned quality. The flexible rubber blanket conforms to the paper's texture, ensuring perfectly smooth and consistent ink coverage every single time.

Offset printing's plate-based system is both its greatest strength and its biggest drawback. It delivers unparalleled consistency for massive print runs, but the upfront cost and time needed to create the plates make it a poor fit for small, fast jobs.

The Digital Printing Method Explained

Digital printing does away with plates and blankets completely, resulting in a much simpler workflow. Instead of separating colours onto different plates, a digital press renders the entire image at once, directly from the source file.

This is what makes Variable Data Printing (VDP) possible, which is a massive advantage for digital. Because each print is created individually, you can change details like names, addresses, or even images from one piece to the next without ever stopping the press.

For instance, if you needed 500 personalised invitations for a conference, digital printing could easily handle adding a unique guest's name to each one. Trying to do that with offset would be virtually impossible and astronomically expensive.

The two main technologies in the digital printing world are:

- Inkjet: This method sprays microscopic droplets of ink directly onto the paper to form the image.

- Toner: This technique uses fine, electrically charged powder that is fused onto the paper with heat.

Both technologies produce fantastic results, especially for short-run projects. In fact, digital printing has come so far that for many jobs, the quality is almost identical to offset. This direct-to-paper process is what makes digital so fast, making it the perfect choice for last-minute marketing materials or event signage when you just can't wait.

Comparing Cost and Turnaround Times

When you're weighing up digital printing vs offset printing, the conversation inevitably comes down to two things: how much it’s going to cost, and how fast you can get it. These two factors are completely intertwined, and getting your head around how they work together is the key to making a smart call for your project. The best choice really hinges on the size of your print run.

For example, think of a real estate agent in Auckland who needs 200 top-notch flyers for an open home this weekend. Digital printing is a no-brainer. The speed is perfect for a tight deadline, and the cost is very reasonable for that small quantity.

On the other hand, imagine a national retailer planning a seasonal catalogue to be sent to all its New Zealand stores. They'll be looking squarely at offset printing to make the massive print run financially sensible.

Understanding the Cost-Per-Unit

The most critical concept to grasp here is the cost-per-unit. This is where the financial differences between digital and offset really show themselves.

Digital printing has virtually no setup costs. As a result, the price to print one copy is pretty much the same as the per-unit cost for printing 100. The price per item stays flat.

Offset printing is the polar opposite. It demands a serious upfront investment to create the custom metal plates and get the press calibrated just right. Because of this high initial cost, printing just a few items is incredibly expensive on a per-unit basis.

But once that setup is done, the cost to print each extra copy is tiny. As your volume climbs into the thousands, that initial setup cost is spread so thin that the cost-per-unit plummets.

The Break-Even Point

This dynamic creates what we in the industry call a "break-even point." It’s the magic number where offset printing actually becomes cheaper than digital. For most standard print jobs in New Zealand, this tipping point usually sits somewhere between 500 and 1,000 units.

The key financial takeaway is simple: for any quantity below this threshold, digital printing offers better value. For anything above it, offset printing’s economy of scale delivers significant savings, making it the more economical choice.

This is why digital printing is the go-to for print runs under the 500 to 1,000 mark here in New Zealand—it completely sidesteps the hefty setup fees of offset. It’s perfect for small businesses or projects where designs are constantly being updated, like marketing postcards where dates and venues might change within a single batch.

Once you’re printing more than 1,000 pieces, offset takes over as the more cost-effective option, as that initial setup cost is absorbed across the large volume, driving down the price per piece. You can explore more about these printing differences in detail to see the full picture.

Speed and Turnaround Time

Just like cost, speed is tied directly to volume and setup. The complex setup for offset printing means turnaround times are naturally longer. Creating plates, proofing, setting up the press, and allowing for proper ink drying can easily take several days, sometimes even weeks for more involved jobs.

Digital printing, without any plates to worry about, offers a much quicker journey from the design file to the finished product. Many jobs can be turned around the same day or within 24-48 hours. This makes it the undisputed champion for any project on a tight deadline.

Let's break it down with a couple of real-world scenarios:

Scenario 1: Urgent Business Cards

- The Job: You need 250 business cards for a networking event in two days.

- Best Choice: Digital Printing. The run is far too small to justify offset’s setup costs, and speed is absolutely critical.

Scenario 2: National Advertising Campaign

- The Job: You need 50,000 promotional brochures for a nationwide mail drop next month.

- Best Choice: Offset Printing. The massive volume brings the cost-per-unit way down, and you have the lead time to accommodate the longer setup.

In the end, your decision boils down to balancing these practical realities. If you need a small batch of flyers for a weekend market, digital is your friend. If you’re planning a large-scale book run, offset is the only way it’ll be affordable. A quick look at your project's volume and deadline will point you straight to the right choice.

A Closer Look at Print Quality and Material Options

When you’re putting your brand’s reputation on paper, the final printed quality is everything. The whole digital vs offset printing debate often boils down to the subtle differences in colour, texture, and overall impact. Your choice doesn’t just affect how sharp your images look; it also dictates the range of materials you can use to bring your creative vision to life.

For many professionals, offset printing is still the gold standard for top-tier quality, especially when getting colours just right is a top priority. It's known for producing rich, consistent colours across massive print runs—a major advantage. This consistency comes from its plate-based process, which guarantees every single copy is a perfect match from the first to the last.

That said, digital printing technology has come a long, long way. Modern digital presses can now produce results that, to the untrained eye, are often indistinguishable from offset, delivering sharp details and vibrant colours for most day-to-day projects.

The Showdown on Colour Accuracy

The real quality difference often comes down to how each method handles colour. Digital printing nearly always uses a four-colour process called CMYK (Cyan, Magenta, Yellow, and Key/Black). It creates a huge spectrum of hues by mixing tiny dots of these four base colours.

This approach is perfectly fine for standard photos and most marketing materials. Where it can sometimes fall short is in reproducing certain brilliant, punchy colours or the very specific shades found in a company’s strict brand guidelines.

Offset printing can also use the CMYK process, but its true strength lies in its ability to use pre-mixed Pantone® Matching System (PMS) inks.

Pantone inks are custom-mixed to an exact formula. This guarantees that a specific colour—like the iconic blue of a famous social media platform or the distinct red of a major soft drink brand—will look identical every single time it's printed, anywhere in the world.

For brands where colour consistency is non-negotiable, that level of precision is absolutely critical.

Materials and Special Finishes

Beyond pure colour, your choice of materials and finishing options adds another layer to the quality conversation. This is where offset printing has traditionally held a clear advantage. The mechanical nature of an offset press means it can handle a much wider variety of paper stocks and other materials.

This includes things like:

- Textured and specialty papers that might jam or refuse to feed correctly in a digital press.

- Thicker cardstocks and less common materials like certain plastics or synthetic papers.

- Custom inks, such as metallic or fluorescent options, that go far beyond the standard CMYK palette.

Here in New Zealand, offset printing is particularly renowned for its superior colour accuracy, largely because it can use specific Pantone colours rather than just CMYK approximations. This is a huge reason why businesses that need exact brand colour matching, like high-end packaging producers or corporate advertising firms, consistently choose offset for their most important work. Offset also opens the door to a broader selection of paper types and finishing touches like foil stamping, embossing, and unique UV coatings. You can read more about how these material options matter for your final product.

The ability to add these special finishes can completely transform a printed piece, turning it from something standard into a memorable, tactile experience.

Common Finishes Better Suited to Offset Printing:

| Finish | Description | Why Offset is Often Better |

|---|---|---|

| Embossing/Debossing | Pressing a design into paper to create a raised or recessed effect. | The heavy pressure required is a natural fit for the mechanical offset process. |

| Foil Stamping | Applying a thin layer of metallic or pigmented foil using heat and pressure. | It integrates more smoothly into the offset production line for large-scale jobs. |

| Spot UV Coating | Applying a glossy varnish to specific parts of a design to make them pop. | Can be applied with greater precision and thickness in an offset workflow. |

While some digital presses are starting to offer limited finishing capabilities, the range and quality you can get through offset printing remain far more extensive. If your project demands a unique texture, a metallic shine, or a three-dimensional element, offset gives you the creative freedom to make it happen. Ultimately, your decision rests on whether the "good-enough" quality of digital meets your needs or if you require the absolute precision and material flexibility of offset to truly do your brand justice.

Practical Use Cases for NZ Businesses

Knowing the theory behind digital versus offset printing is useful, but the real test is applying it to your day-to-day business needs. For businesses here in New Zealand, choosing the right method can directly impact your budget, help you hit those tight deadlines, and ensure your printed materials look exactly how you envisioned them.

Let's put the technical details aside for a moment and walk through some common scenarios. We’ll look at when digital printing is the clear winner and when offset is the only logical choice. This should give you a solid framework for making your own printing decisions.

When Digital Printing Is the Smart Choice

Digital printing really shines when you need speed, flexibility, and affordability for smaller jobs. It’s built for last-minute requests, short print runs, and projects that need a personal touch.

Think about these situations for Kiwi businesses:

-

Urgent Event Materials: An event company in Wellington has a conference in three days and needs 300 high-quality programmes. The tight deadline and relatively small quantity make digital the only realistic option. The fast turnaround gets the job done without the expensive setup of offset printing.

-

Personalised Direct Mail Campaigns: A Queenstown real estate agent is sending out 500 customised flyers to local homeowners. Each flyer needs the recipient's name and a unique property photo. Digital printing’s variable data capability handles this kind of personalisation effortlessly and affordably.

-

Small eCommerce Business Packaging: A Christchurch startup selling artisanal soaps needs branded sleeves for a new product test. They only want 200 sleeves for each new scent to see how they sell. Digital printing lets them order small, on-demand batches, so they avoid being stuck with unused stock and a big upfront bill.

For many NZ businesses, embracing digital printing is part of a wider small business digital transformation. It aligns perfectly with a more agile and responsive way of doing business.

The real magic of digital printing is its agility. If your project involves a small quantity (usually under 500), a tight deadline, or any kind of personalisation, digital is almost always the most efficient and cost-effective way to go.

When Offset Printing Delivers Unbeatable Value

For the big jobs, offset printing is still king. When you need large volumes and perfect colour consistency, its strengths are impossible to ignore. This is where the initial investment in plates pays off handsomely.

Here are some classic examples where offset is the better choice:

-

High-Volume Catalogues and Magazines: A nationwide retailer based in Auckland needs 50,000 copies of its seasonal catalogue. At this scale, the cost per item with offset printing drops dramatically, making it far cheaper than digital. Critically, it also guarantees the brand’s specific colours look identical in every single catalogue, from Invercargill to Kaitaia.

-

Premium Corporate Brochures: A financial services firm in Tauranga is creating 5,000 premium annual reports for its stakeholders. They need their logo printed in a specific Pantone colour on a special textured paper stock to convey a sense of prestige. Offset printing handles these custom elements with ease, delivering a level of quality that reinforces the company's professional image.

-

Large-Scale Product Packaging: A food manufacturer in the Hawke's Bay is launching a new muesli bar and needs 100,000 identical boxes. Consistency across the entire production run is vital for standing out on a competitive retail shelf. Offset delivers this uniformity at a price point that simply can't be beaten at such a large quantity.

The Future of Printing Technology

The printing world is always moving, and the tug-of-war between digital printing vs offset printing is constantly shifting. While the classic methods aren't going anywhere, new technologies are creating some seriously exciting possibilities. Looking ahead helps you know which innovations to keep an eye on and how to plan your future print jobs.

The future isn't about one method winning out over the other; it’s more about each finding its specialised place. We’re seeing a clear trend where technology is sharpening the core strengths of both digital and offset, making them more powerful and efficient for their intended roles. For businesses here in New Zealand, that translates to more choice and better outcomes.

This shift is happening as the broader industry itself changes. Market data on the New Zealand printing sector shows a slight overall contraction, shrinking by about 2.2% annually between 2020 and 2025. But even with that decline, the use of digital printing is on the rise, largely because it’s so well-suited for smaller, more flexible print runs. You can discover more about NZ printing market trends to get a better feel for this change.

The Rise of Smarter Digital Printing

Digital printing’s future isn’t just about getting faster—it’s about getting smarter and more personal. The technology is advancing in leaps and bounds, pushing the limits of what you can do with on-demand and customised projects.

Here are a few key advancements to watch:

- Advanced Variable Data Printing (VDP): We're already past just printing someone's name on a flyer. The next generation of VDP will drive hyper-personalised campaigns where the images, offers, and even the core message are unique to each person, all printed at incredible speeds.

- Wider Material Compatibility: Digital presses are getting much better at handling different paper stocks, textures, and synthetic materials that used to be strictly offset territory.

- Integrated Finishing: Imagine a single machine that prints, cuts, folds, and adds a spot gloss finish in one smooth process. New digital systems are being built to do just that, slashing production times for complex, short-run jobs.

The next wave of digital tech is all about making hyper-personalisation available at scale. It gives businesses the power to create marketing materials so relevant they feel like a one-on-one conversation, something that used to be impossible for all but the biggest campaigns.

How Offset Printing Is Adapting

Offset printing isn't just sitting back and watching. It's becoming more automated, efficient, and sustainable to hold its ground for large-volume work. The main goal is to fine-tune its already reliable process to cut down on waste and speed up delivery.

Innovations in the offset space include:

- Increased Automation: Modern offset presses are now kitted out with automated plate changing and computer-managed ink levels. This drastically reduces the long setup times that have always been offset's biggest hurdle.

- Sustainable Practices: The industry is making a real push towards greener solutions. Think soy-based inks and chemical-free plate processing, all designed to minimise its environmental impact.

- Hybrid Technologies: We’re starting to see "digital offset" presses emerge. These machines aim to give you the best of both worlds by blending the plate-free setup of digital with the quality and raw speed of offset.

In the end, the future of printing looks like a partnership. Digital will continue to be the star for fast, flexible, and personalised printing. At the same time, a leaner and greener offset process will remain the champion for massive projects where uncompromising quality and cost per piece are the most important factors.

Frequently Asked Questions

Even after weighing up the main differences between digital and offset printing, you probably still have a few questions. Let's tackle some of the most common queries we get from businesses here in NZ, giving you the clear answers you need to make the right call.

Can I Do a Small Test Run with Offset Printing?

While you technically can, it's almost always a terrible idea for your budget. The entire upfront cost of creating the custom metal plates and calibrating the press would be loaded onto just a few copies, making each one eye-wateringly expensive.

For test runs, proofing your design, or getting a single prototype made, digital printing is always the better choice. It’s the perfect way to get a high-quality sample or a small batch in your hands without the massive financial commitment of an offset setup.

Which Printing Method Is Better for the Environment?

This is a tricky one, as the environmental impact of digital versus offset printing isn't black and white. Each has its own pros and cons.

- Offset Printing: Historically, this method used more chemical solvents for cleaning the presses and creating plates. However, the industry is moving in a greener direction, with many printers now using soy-based inks and chemical-free plate processing to lessen their footprint.

- Digital Printing: For short runs, digital is the clear winner on waste. There are no "make-ready" sheets needed to get the press up to colour, so almost every sheet is a usable product. It also enables print-on-demand, which drastically cuts down on the waste that comes from over-ordering.

So, for smaller jobs, digital is generally the more eco-friendly option. But for huge print runs, a modern, efficient offset printer can be surprisingly sustainable.

How Does Variable Data Printing Actually Work?

Variable Data Printing (VDP) is a powerful feature exclusive to digital printing. It allows you to customise elements like text, graphics, or images on each individual printed piece, all without ever stopping the press.

It works by connecting a master design template to a database—think of a simple spreadsheet with names, addresses, or member numbers. The digital press then pulls the data from each row of the spreadsheet and inserts it into the designated fields on your design as it prints. This is how businesses create personalised direct mail campaigns, print uniquely numbered tickets, or produce customised certificates. This kind of one-to-one personalisation is simply impossible with offset, where the printing plate is fixed and can't be altered mid-run.

By merging a master template with a data file, VDP produces marketing materials that feel genuinely unique to each person who receives them. This capability is precisely why digital printing is the go-to for targeted campaigns where making a personal connection is everything.

At SONI DESIGN, we know that every project has its own unique demands. Whether you need the quick turnaround and flexibility of digital or the unmatched quality and cost-effectiveness of offset for a large run, our team is here to guide you. Let’s create something extraordinary that reflects your unique story and vision!

Leave a Comment

Stay home & get your daily

needs from our shop

Start You'r Daily Shopping with Nest Mart

Best prices & offers

Orders $50 or more

Free delivery

24/7 amazing services

Great daily deal

When you sign up

Wide assortment

Mega Discounts

Easy returns

Within 30 days