Your cart is currently empty.

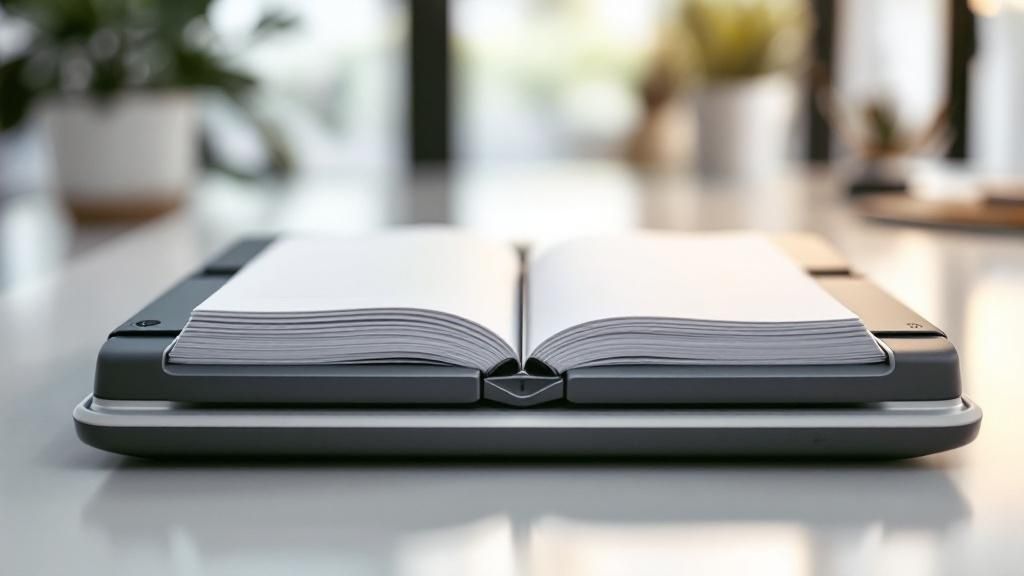

At its core, a booklet binding machine is a specialised tool designed to take a simple stack of printed pages and turn it into a professional, finished document. Think of it as the final, crucial step that transforms loose sheets into a polished booklet, a tidy report, or a compelling presentation that's easy to read and handle.

From Loose Pages to Polished Booklets

Turning that pile of loose pages into a professional-looking document is a critical finishing touch for any business. It's best to see a booklet binding machine not just as another piece of office equipment, but as a powerful tool for creating something truly tangible. It elevates your printed work in the same way a custom frame enhances a piece of art.

The right binding method can instantly transform internal reports, client proposals, and marketing materials from mere printouts into high-impact assets. That polished finish really does make a significant difference in how your documents are perceived, handled, and even stored.

Why Presentation Matters

A professionally bound document immediately signals quality and a keen eye for detail. This small investment in presentation can pay huge dividends for your company's image.

Here’s what you gain:

- Improved Readability: Pages can lay flat and turn smoothly, creating a much better experience for the reader.

- Enhanced Durability: A secure binding protects your pages, preventing them from getting lost or damaged and extending the life of your document.

- Professional Appearance: A clean, organised booklet is a direct reflection of your brand and its commitment to high standards.

The goal is to create something that not only communicates information but also feels substantial and important in the hands of your reader. It’s the difference between a simple handout and a valuable resource.

Setting the Stage for Your Success

Understanding the options available is the first step toward choosing the right solution. This guide will walk you through the most common binding styles, from the flexible and editable comb binding to the sleek, secure finish of wire binding. We'll also cover saddle-stitching, which is the go-to standard for thinner booklets and magazines.

By the end, you'll have the know-how to select the perfect booklet binding machine or method that lines up with your project needs, budget, and the impression you want to make. It’s all about ensuring every document you produce is a professional success.

Matching a Binding Style to Your Project

Picking the right binding method is a bit like choosing the right tool for a job. You wouldn't use a sledgehammer to hang a picture frame, would you? In the same way, the binding for a simple internal memo should be different from what you'd use on a high-stakes client proposal. Your choice should always reflect the document's purpose, its audience, and how long you need it to last.

The first step is getting to know the main types of binding you can create with a booklet binding machine. The four most common methods you’ll come across are comb, coil (often called spiral), wire, and saddle-stitching. Each one strikes a different balance between looks, durability, and practical use.

Let's dive into these options so you can make the right call for your next project.

Comb Binding: The Editable Favourite

Comb binding is easily one of the most popular and versatile choices out there. It’s a go-to for things like internal documents, training manuals, and early drafts. The process uses a plastic, multi-ringed "comb" that slots neatly into rectangular holes punched along the edge of your paper stack.

The standout feature of comb binding is its editability. You can use your machine to easily open the comb back up, allowing you to add, remove, or reorder pages whenever you need. This makes it an absolute lifesaver for documents that are constantly evolving.

- Best For: Internal reports, training materials, notebooks, and draft proposals.

- Look & Feel: Professional but primarily functional. The plastic combs are available in a wide range of colours to match your branding.

- Durability: It's moderately durable. Perfect for everyday office use, but it might not hold up to really heavy, long-term wear and tear.

Coil and Wire Binding: The Durable Duo

When you need a step up in both durability and presentation, coil and wire binding are your best bets.

Coil binding, or spiral binding as it's often known, uses a continuous plastic or metal coil that's threaded through a series of round holes. This method creates an incredibly tough document. Its real superpower is that it allows pages to fold back on themselves a full 360 degrees, which is fantastic for things like workbooks and manuals where you need to take notes.

Wire binding, sometimes called twin-loop or Wire-O, uses a C-shaped wire spine that’s squeezed shut into a secure circular shape. It delivers a very clean, high-end finish that many businesses lean on for important documents shared outside the company. The pages also lay perfectly flat, but they don't quite fold all the way back with the same ease as a coil-bound book.

Key Takeaway: Wire binding gives you a premium, secure finish that’s perfect for client-facing documents like formal presentations and annual reports. Coil binding, on the other hand, offers unmatched durability and flexibility, making it ideal for frequently used items like reference guides and training workbooks.

Saddle Stitching: The Booklet Standard

Saddle-stitching isn't quite a "binding" in the same way as the others, but it’s the classic method for creating booklets. Think of a standard magazine or a theatre programme. The process involves folding sheets of paper in half and then stapling them right along the centre fold.

This approach is quick, cost-effective, and gives you a slim, professional-looking booklet. The main limitation is page count. It works best for documents that are under 64 pages or so, though this depends on how thick your paper is. If you try to saddle-stitch too many pages, you’ll run into an issue called "creep," where the inner pages start to stick out further than the outer ones.

To help you see how these options stack up at a glance, we've put together a simple comparison table.

Binding Machine Type Comparison

| Binding Type | Best For | Durability | Page Turning | Cost |

|---|---|---|---|---|

| Comb | Internal reports, editable documents | Moderate | Lays flat | Low |

| Coil (Spiral) | Manuals, notebooks, workbooks | High | Lays flat, 360° rotation | Low to Medium |

| Wire-O | Proposals, presentations, calendars | High | Lays flat | Medium |

| Saddle-Stitch | Booklets, magazines, brochures | Low | Standard booklet style | Very Low |

This table should make it clearer which binding style aligns best with your project’s needs—from durability to budget.

This image provides a great visual breakdown of how these methods compare on key performance metrics.

As the data shows, there’s a trade-off to consider. Some methods are much faster, while others are built to handle thicker paper, highlighting the balance you need to find with any machine.

Ultimately, choosing the right booklet binding machine for your business in New Zealand comes down to getting that balance of cost, appearance, and function just right. By carefully matching the binding style to what each project demands, you can ensure every document you create not only looks professional but also does its job perfectly.

Essential Features to Compare

Once you’ve settled on a binding style, it’s time to get into the details—the technical specs that really determine how a machine performs. Choosing a booklet binding machine isn't so different from picking out a new car. You wouldn't buy a small hatchback to haul furniture, and you certainly don't need a giant truck for a quick trip to the dairy. The goal is to match the machine’s capability to the kinds of jobs you'll actually be doing.

This means you need to look past the binding type and focus on the core features that affect your day-to-day workflow. The right machine will make your projects feel effortless, while the wrong one can quickly become a source of frustration and hold-ups. Getting this part right helps you avoid the classic pitfall of buying a machine that’s either too underpowered for your needs or far too expensive and complicated for your typical workload.

Ultimately, the most important features come down to two things: how much work the machine can handle and how versatile it is.

Punch and Binding Capacity

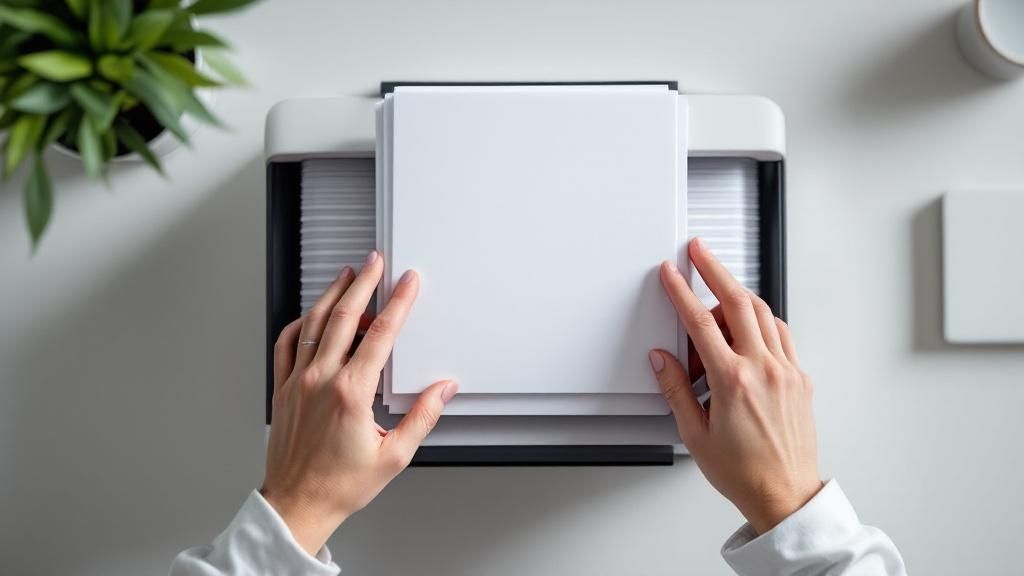

First, let's talk about the machine's "engine"—its raw power. This is measured by two key metrics: punch capacity and binding capacity. These two numbers tell you almost everything you need to know about how well a machine will cope with your project volume and document thickness.

-

Punch Capacity: This is simply the maximum number of sheets the machine can punch holes through in one go. A small manual machine might only manage 6-8 sheets, but a heavy-duty electric model could power through 25 sheets or more at a time. A higher punch capacity makes a huge difference in speed when you're dealing with big documents.

-

Binding Capacity: This refers to the maximum thickness of a booklet the machine can bind. It's usually listed as a total page count or the diameter of the biggest spine it can handle. A machine with a generous binding capacity gives you the freedom to create everything from thin brochures to thick company reports.

Think of it this way: punch capacity is your machine's horsepower, dictating how fast you can work. Binding capacity is its cargo space, defining how big of a project you can take on.

Adjustability and Operation

Beyond raw power, a good binding machine needs to be flexible. It's unlikely all your projects will use the same paper size, so a machine that can adapt is incredibly useful. Look for features like adjustable edge guides and disengageable punching pins. These let you easily switch between A4, A5, or even custom-sized paper without ending up with awkwardly placed, off-centre holes.

Finally, you’ll need to decide between manual and electric operation.

- Manual Machines: Operated with a hand lever, these are affordable, portable, and perfectly suited for small volumes or occasional use.

- Electric Machines: These use a foot pedal or a button to do the punching, which takes a lot of the physical effort out of the equation. If you're binding frequently or in large batches, an electric model is the obvious choice to reduce fatigue and speed things up.

By carefully considering these features, you can make an informed decision and invest in a booklet binding machine that's a perfect fit for your business—ready to handle any project you throw at it.

The Binding Machine Market in New Zealand

Before you invest in any significant piece of business equipment, it pays to understand the local landscape. This is especially true when it comes to booklet binding machines. For any Kiwi business, taking a look at recent trends here in New Zealand gives you the context you need to make a smart call on your purchase, timing, and budget. The market isn't static; it moves and shifts, directly affecting the supply, availability, and price of your next office workhorse.

Getting a clear picture of these economic movements helps you make a much more informed choice. Think of it this way: knowing when prices are dipping or when supply chains are feeling the pinch lets you plan your purchase strategically. It’s not just about buying a machine; it's about making a sound financial move that fits with what’s happening in the New Zealand business world right now.

Recent Import and Price Fluctuations

The local market for binding equipment has definitely seen some ups and downs lately. This has a direct knock-on effect for businesses looking to buy a new booklet binding machine. For instance, recent economic data shows some pretty big swings in both the number of machines being brought into the country and what they’re selling for.

In 2022, the total number of book-binding machines imported into New Zealand fell to around 2,900 units. That’s a sharp drop of 41.7% from the year before. At the same time, the average price took a nosedive, plummeting to just $27 per unit—a massive 78% decrease compared to 2021. If you're interested in the raw numbers, you can dig deeper into these market dynamics on IndexBox.io.

So, what does all this mean for your business? Put simply, these figures show a market that can change on a dime.

A sudden drop in imports could hint at supply chain issues or a change in local demand. On the other hand, a big price drop might be the perfect window of opportunity for your business to grab new equipment at a fantastic price. Keeping an eye on these trends is crucial.

Navigating the Local Market

For any New Zealand business, this kind of market volatility really highlights why doing your homework is so important. Here’s how you can turn this knowledge into a real advantage:

- Time Your Purchase: If you see prices are low, it could be the ideal moment to invest. But if import numbers are down, you might need to prepare for longer wait times or start looking at different suppliers.

- Assess Equipment Value: Wild price swings can impact the resale value of your existing gear. Understanding these trends helps you figure out the true, long-term cost of owning a machine.

- Talk to Local Suppliers: Building a good relationship with New Zealand-based suppliers, like us here at Soni Design, can give you priceless insights and help you get ahead of any supply chain headaches.

By keeping your finger on the pulse of the local market, you put your business in the best position to find great value and sidestep potential problems. It ensures your investment in a booklet binding machine is not just a good one, but a timely and wise one too.

New Zealand's Global Trade Position

While many New Zealand businesses rely on imported equipment, it's worth taking a moment to see where our own industry stands globally. When we talk about the booklet binding machine market, New Zealand has carved out a small but important niche for itself. We're not trying to go head-to-head with the manufacturing giants; instead, it's about doing what we do best—finding a specific need and serving it exceptionally well.

Understanding this dynamic gives local buyers some valuable context. It shows that even though our national output is modest compared to the big players, we have a distinct and active manufacturing scene right here at home. This is helpful for any Kiwi business looking to support local or simply get a clearer picture of the supply chain for these essential tools.

A Niche Exporter on the World Stage

The best way to describe New Zealand’s role in the global trade of binding machinery is that of a specialised, small-scale exporter. We aren't exactly flooding the international market, but we are making our mark.

This often means our local manufacturers concentrate on custom solutions or certain types of machines designed for very specific industry needs, rather than churning out mass-produced models. Think of it as craftsmanship over mass production.

This specialisation can be a huge plus. It points to a focus on quality, innovation, and the kind of direct customer relationships that Kiwi ingenuity is known for. For a local business, that could mean getting your hands on bespoke equipment or receiving more personalised service from a manufacturer who genuinely gets the New Zealand market.

By focusing on niche areas, New Zealand manufacturers can compete on craftsmanship and specific solutions rather than volume, creating unique value in the global marketplace. This is a common strategy for smaller economies to maintain a competitive edge.

Looking at the Trade Data

When you dig into the numbers, this story of specialisation really comes to life. The export data confirms both our niche presence and the scale of our contribution to the international market.

In 2023, New Zealand's exports of book-binding machinery, which includes book-sewing machines, were valued at roughly $235,000 USD. This made us the 52nd largest exporter in the world for this particular category. If you’re curious, you can dive deeper into these figures and see how New Zealand stacks up against other countries on the OEC.world trade platform.

That figure isn't a sign of weakness; it’s a clear indicator of a specialised industry. It tells you that a "Made in New Zealand" label in this sector likely means the product was built with a specific purpose or customer in mind. What's more, this small scale points to some exciting potential for growth—both in meeting our own domestic needs and possibly expanding into new overseas markets. Supporting local could very well mean investing in that future.

Buying a Machine vs. Using a Service

So, you've reached the big question: do you buy your own machine or just outsource the work? This is a classic "buy versus hire" puzzle, and honestly, there's no single right answer. It all boils down to your specific needs—your budget, how often you’re binding, and how quickly you need things done. Finding your own break-even point is the key.

For a lot of people, especially small businesses that only need a few reports a year or a one-off print run for a marketing campaign, using a professional printing service is a no-brainer. It's convenient, you get access to top-of-the-line equipment without the hefty price tag, and you don't have to worry about maintenance or training someone to use the gear. It just makes financial sense.

When an In-House Machine Makes Sense

But what if you're constantly binding documents? That’s where the equation starts to flip. Think of a busy real estate agency that churns out property brochures every week, or a school that needs to prepare new course packs for students all the time. In those cases, having an in-house booklet binding machine isn't just a convenience; it's a game-changer.

The ability to make last-minute changes and get documents finished on the spot gives you a level of control and speed that an outside service just can't match.

Owning your own machine puts you in the driver's seat. It offers unmatched flexibility for customisation and on-demand production, turning a potential bottleneck into a streamlined part of your workflow.

If you’re leaning towards buying, it's smart to explore all the financial angles. Comparing options like leasing vs. buying equipment is a great place to start. It’s also interesting to note that while it's a niche market, New Zealand has a solid foothold in this space. In 2022, the country exported around $117,100 USD worth of book-binding machinery, showing there’s a local pulse in this specialised sector. You can dig into these trade dynamics over at Trading Economics.

To figure out the best path for you, just weigh up these key factors:

- Volume and Frequency: How many booklets are you making, and how often?

- Urgency: Do you need things done yesterday, or can you wait?

- Customisation: Are your projects standard, or do they need a personal touch?

- Long-Term Costs: Over a year or two, will the machine investment pay for itself?

Frequently Asked Questions

Jumping into the world of booklet binding can feel a bit daunting, and it's natural to have questions. You want to make sure you're picking the right tool for your office. Let's tackle some of the most common queries to help clear things up and get you on the right track.

What Is the Easiest Booklet Binding Machine for a Beginner?

If you're just dipping your toes into creating your own documents, a comb binding machine is almost always the best place to start. The whole process is straightforward and, best of all, incredibly forgiving.

The real magic is that the plastic combs can be easily reopened. This means if you spot a mistake or need to add an extra page later on, it’s no problem at all. That flexibility makes it a fantastic, low-stress option for any office new to the game.

How Much Maintenance Do Binding Machines Require?

You'll be pleased to hear that most manual and small electric binding machines are surprisingly low-maintenance. Keeping them in top shape usually comes down to just a couple of simple habits.

Really, the main things you need to do are empty the little tray that catches the paper chads from punching and occasionally oil the punching mechanism to keep it running smoothly. Of course, it's always smart to have a quick look at your machine's specific user manual for the manufacturer's advice.

A well-maintained machine is a reliable one. A few moments of basic care can prevent jams and ensure your equipment provides years of consistent, high-quality performance, protecting your investment.

Can I Bind Hardcover Books with a Standard Office Machine?

In short, no. Your standard office booklet binder isn't built for making hardcover books. These machines are specifically designed to work with documents that have flexible, soft covers.

Creating a proper hardcover book is a much more involved craft that demands specialised gear, like thermal binding systems or heavy-duty book-block machines. These are in a completely different league from the typical comb, coil, or wire binders you'd find in an office and are built for a much larger scale of production.

At SONI DESIGN, we understand the power of a professionally finished document. If you're ready to take control of your printing and presentation, explore our range of design and print solutions to find the perfect fit for your business. Discover our services at sonidesign.co.nz and let's create something extraordinary together.

Leave a Comment

Stay home & get your daily

needs from our shop

Start You'r Daily Shopping with Nest Mart

Best prices & offers

Orders $50 or more

Free delivery

24/7 amazing services

Great daily deal

When you sign up

Wide assortment

Mega Discounts

Easy returns

Within 30 days