Your cart is currently empty.

An ACM panel in NZ is shorthand for Aluminium Composite Material, a cutting-edge cladding and signage material known for its clever sandwich-like design. It's a product that perfectly blends a lightweight profile with serious strength, which is why you see it used so often across New Zealand's varied architectural projects.

What Is an ACM Panel and Why Is It So Popular in New Zealand?

Think of an ACM panel as a high-tech architectural sandwich. The two outer layers—the ‘bread’—are thin but tough sheets of aluminium. These sheets are the panel's first line of defence, giving it weather resistance, structural stability, and that clean, modern look that architects and designers are after.

Between these two aluminium skins is the ‘filling’: a lightweight core. This core is what really defines the panel's character. It's the key to its rigidity, its low weight, and, crucially, its fire safety performance—a massive consideration under the New Zealand Building Code.

This simple but effective structure results in a material that's surprisingly light for how strong and flat it is. It's a winning combination that has made the ACM panel a go-to choice for projects all over Aotearoa.

The Rise of ACM Panels in NZ Architecture

You don't have to look far to see just how versatile ACM panels are in Kiwi building design. They’re everywhere. You’ll find them on the sleek facades of high-rises in Auckland's CBD and framing the sharp, professional-looking shopfronts in Wellington and Christchurch.

Their popularity isn't an accident. It comes down to a few key benefits that tick all the right boxes for our local construction industry.

- Lightweight Construction: ACM panels are a fraction of the weight of solid aluminium sheets with the same level of rigidity. This makes a real difference by reducing the structural load on a building’s frame and foundation, which can simplify the engineering and even bring down construction costs.

- Design Flexibility: This is where ACM really shines. The material can be cut, folded, bent, and routed into all sorts of complex shapes and curves. It hands architects incredible creative freedom to design dynamic, three-dimensional facades that would be a nightmare—or just too expensive—to create with other materials.

- Aesthetic Versatility: The sheer range of colours, textures, and finishes is incredible. You can get anything from standard solid and metallic colours to finishes that mimic woodgrain or natural stone. There are even prismatic options that cleverly shift colour depending on how the light hits them.

It's also worth pointing out their role in overall building performance, including things like commercial building energy efficiency. A well-installed ACM facade system can boost a building’s thermal insulation, helping to better manage energy use.

By bringing together strength, low weight, and almost limitless design possibilities, ACM panels deliver a solution for cladding, signage, and interior fit-outs that is both highly functional and visually striking. This blend of practicality and aesthetics is exactly why the ACM panel has become such a staple in New Zealand's architectural toolkit.

As we’ll get into, the specific type of core material has become a critical point of regulation. This has fundamentally changed how and where these panels can be used safely in our buildings. Getting your head around these rules is the first step to specifying them correctly.

Navigating the NZ Building Code for ACM Panel Compliance

Getting your head around the rules for using ACM panels in NZ isn't just a box-ticking exercise—it’s the single most important part of the job. The New Zealand Building Code lays down some very clear, non-negotiable lines in the sand when it comes to fire safety for external cladding. Getting this wrong can bring a project to a screeching halt and cause major headaches with sign-off, insurance, and most importantly, people's safety.

The heart of the matter is the panel's core. It's the "filling" in the ACM sandwich that dictates how the panel will behave when things get hot. This distinction is now the centrepiece of our building code, drawing a clear line between what’s acceptable and what’s not.

These regulations didn't just appear out of nowhere. For years, Aluminium Composite Panels were a go-to choice across New Zealand for their sharp looks and practicality. But as their use skyrocketed, so did the need to look closer at the fire risks, especially after some devastating building fires overseas.

An investigation by the Insurance Council of New Zealand (ICNZ) brought the issue into sharp focus. Before early 2017, it wasn't uncommon to see polyethylene (PE) core panels on buildings taller than 10 metres. A crucial amendment to the NZ Building Code changed everything, restricting these combustible panels to low-rise buildings under 7 metres and demanding fire-rated (FR) panels for anything taller. It was a massive step forward for building safety.

The All-Important Difference: PE Core vs. FR Core

When we talk about ACM panels and fire safety, it really boils down to two main types of cores: Polyethylene (PE) and Fire-Rated (FR).

-

Polyethylene (PE) Core: Think of this as a solid thermoplastic, basically a form of plastic. When it gets hot enough, it can melt, drip, and release a huge amount of flammable energy. This can fuel a fire and help it spread rapidly up the side of a building. Because of this risk, its use in New Zealand is now heavily restricted.

-

Fire-Rated (FR) Core: This is a completely different beast. The core is packed with a high percentage of non-combustible minerals, like aluminium hydroxide, all held together with a small amount of polyethylene binder. These minerals are the key—when heated, they release water vapour, which actively cools the panel and slows down combustion.

This fundamental difference is exactly why the NZ Building Code now insists on FR core panels for most multi-level building projects.

The core of the issue is the core of the panel. For any building in New Zealand that isn't a low-rise structure, specifying a fire-rated mineral core isn't just a best practice—it's a legal requirement designed to protect property and save lives.

Key Regulations and Building Height

The New Zealand Building Code uses building height as the primary yardstick for deciding which ACM panels are allowed.

As a general rule of thumb, combustible cladding like PE-core ACM panel NZ products cannot be used on buildings with a floor height of 7 metres or more above the lowest ground level. If your building hits that mark or goes higher, you must use a fire-rated panel that has passed specific, rigorous testing.

You'll find these requirements detailed in the Acceptable Solutions and Verification Methods of the building code. These are the documents that architects, builders, and council inspectors live by to ensure everything is up to spec. For a wider view on this topic, check out this comprehensive guide to navigating building codes and regulations.

Proving Performance: Fire Testing and Standards

So, how do you prove a panel is genuinely "fire-rated"? It has to go through some serious testing. In New Zealand, the gold standard for assessing the fire performance of building materials is ISO 5660-1.

Often called the cone calorimeter test, this process subjects a sample of the material to a controlled radiant heat source and measures a few critical things:

- Time to Ignition: How long does it take to actually catch fire?

- Heat Release Rate: How much energy does it pump out as it burns? This is the big one for predicting fire spread.

- Smoke Production: How much smoke does it create? This is vital for ensuring people can get out safely.

The results from this test determine whether an ACM panel meets the grade for use on buildings over 7 metres. When you're sourcing panels, your supplier absolutely must provide a current and valid ISO 5660-1 test certificate for the exact product you plan to use.

Without that piece of paper, you can't prove compliance, and your project won't get its Code Compliance Certificate (CCC). It’s that simple. Vetting your materials and suppliers isn’t just good practice; it’s an essential part of your project's due diligence.

Understanding Core Types and Fire Performance Ratings

To really get to grips with ACM panel safety, we need to look past the regulations and dig into the science of the panel’s core. This is where the real difference lies. The core material is the single biggest factor in how a panel behaves in a fire, and the choice between a modern, mineral-based Fire-Rated (FR) core and an older polyethylene (PE) core is a critical one.

A PE core is, in simple terms, a solid sheet of plastic. When it gets hot, it does what you’d expect plastic to do: it melts, drips, and releases a huge amount of flammable gas. This can act like a fuel source, helping a fire climb a building's exterior with terrifying speed. It’s exactly this high-risk behaviour that led to PE cores being all but banned for most construction in New Zealand.

An FR core, on the other hand, is engineered from the ground up to resist fire. It's packed with non-combustible mineral compounds—often 80% or more—like aluminium hydroxide. Think of these minerals as a built-in sprinkler system. When heated, they trigger a chemical reaction that releases water vapour. This process actively cools the panel and smothers the fire, slowing combustion right down and preventing flames from spreading.

Decoding Fire Performance Metrics in NZ

So, how do we measure this difference in a way that's useful on a construction site? Here in New Zealand, we rely on standardised tests and clear, objective numbers. When you're looking at the technical data for an ACM panel in NZ, you’ll see specific fire performance ratings. Knowing what these mean is crucial for ensuring you’ve got a compliant, safe product.

The go-to test in New Zealand is ISO 5660-1. This gives us hard data on several critical factors:

- Heat Release Rate (kW/m²): This is the big one. It measures how much energy a material gives off when it burns. A lower number means the panel contributes less fuel to a fire.

- Smoke Production Rate: This looks at how much smoke the material creates. Thick, toxic smoke is a major life-safety risk, blocking escape routes and causing harm through inhalation.

- Time to Ignition: This tells you how long the material can be exposed to intense heat before it actually catches fire, buying valuable time for evacuation.

These aren't just abstract numbers; they provide the concrete evidence needed to make safe and compliant decisions without any guesswork.

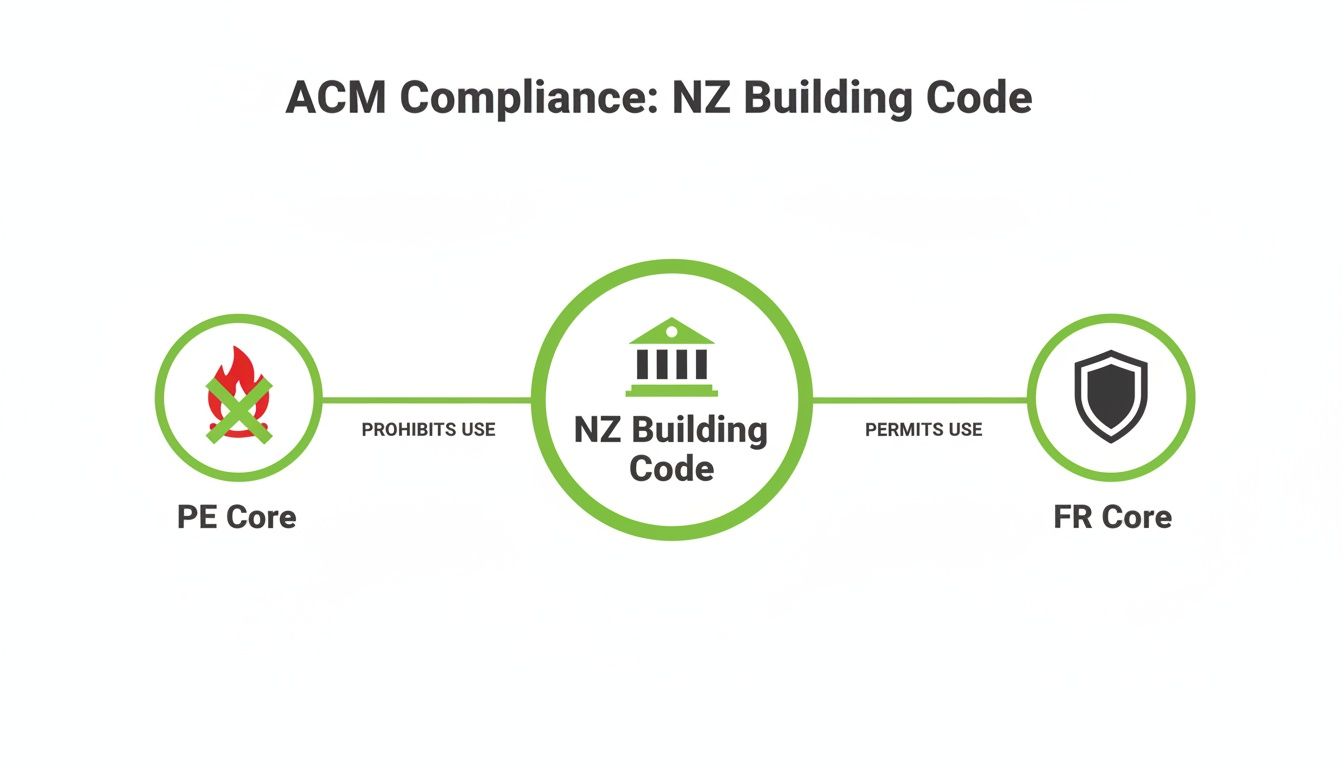

Here's a quick visual guide that sums up the New Zealand Building Code's position on ACM panel cores.

As you can see, the message is clear: for most multi-level buildings, fire-rated cores are a must-have for both safety and compliance.

For a clearer picture, let's compare the most common core types you'll encounter for projects in New Zealand.

Comparing ACM Panel Core Types for NZ Projects

| Core Type | Composition | Fire Performance | Typical NZ Application |

|---|---|---|---|

| PE (Polyethylene) | 100% thermoplastic polyethylene | Highly combustible; melts, drips, and spreads flames. | Generally not permitted for external wall cladding on multi-level buildings. Limited to low-risk uses like temporary signage. |

| FR (Fire-Rated) | Mineral-filled core (e.g., aluminium hydroxide) mixed with a small amount of polyethylene binder. | Significantly delays combustion and limits fire spread. Releases water vapour when heated. | Widely used for compliant external facades, commercial buildings, and multi-storey apartments. |

| A2 (Non-Combustible) | >90% non-combustible mineral content. | Superior fire resistance with minimal contribution to a fire. Little to no smoke production. | Specified for high-rise buildings, critical infrastructure, and high-risk projects where maximum fire safety is non-negotiable. |

This table shows a clear progression in fire safety, from the restricted PE core to the high-performance A2 core.

Connecting Ratings to Building Importance Levels

These technical ratings have a direct impact on where a panel can be used. The NZ Building Code classifies buildings by Importance Levels (IL), from IL1 (a farm shed) to IL5 (a hospital or emergency service building). The higher the IL, the tougher the fire safety rules.

For instance, the Code sets very specific benchmarks. According to official MBIE guidance, panels on buildings in Importance Levels 1 and 2 must be able to withstand a radiant heat flux of 30 kW/m² for at least 15 minutes without igniting. Buildings with higher importance levels have even stricter requirements. You can read the detailed ACP guidelines from MBIE for the full breakdown.

By understanding the science behind the core and the metrics used to test it, you can read any technical data sheet with confidence. This puts you in the driver's seat, allowing you to choose an ACM panel that looks great and, more importantly, meets the strict safety and compliance demands of your New Zealand project.

Choosing the Right Panel Finish for Durability and Aesthetics

While the core of an ACM panel in NZ is all about fire safety, it’s the surface finish that truly defines the building's character. This coating is far more than just a lick of paint; it's a high-tech shield that dictates how the panel will look, how it will last, and how much work it’ll take to maintain.

Getting the finish right is a big deal here in New Zealand. Our intense UV levels and corrosive coastal salt spray are notoriously tough on building materials. The finish has to be up to the task, fighting off fading, chalking, and corrosion to keep the facade looking its best year after year.

Ultimately, the choice comes down to balancing your design vision with the hard realities of the building’s location, its exposure to the elements, and your budget. A beautiful finish that can't handle the local climate will quickly become a costly headache.

The Industry Standards: PVDF and FEVE

When you're talking top-tier coatings for ACM panels, two names always come up: PVDF and FEVE. They’re both premium fluoropolymer paints, famous for their incredible durability, though each has its own unique strengths.

PVDF (Polyvinylidene Fluoride) is the seasoned veteran in the industry, with a track record stretching back decades. Its superpower is an incredible resistance to chalking and fading under UV light. The carbon-fluorine bond in its molecular structure is one of the toughest out there, meaning it holds its colour exceptionally well, even under the fierce New Zealand sun.

FEVE (Fluorinated Ethylene Vinyl Ether) is a newer innovation that brings a bit more aesthetic flexibility to the table, offering a broader range of gloss levels than PVDF. It delivers the same outstanding colour retention and weatherability, but with added resistance to chemicals and abrasion. This makes it a brilliant choice for high-traffic areas or environments where it might get exposed to pollutants.

In New Zealand's varied climate, both PVDF and FEVE coatings offer superior protection. For projects in coastal areas like Tauranga or Wellington, their robust resistance to salt spray is essential for preventing corrosion and maintaining the building's aesthetic integrity over its lifespan.

To make the choice clearer, it helps to see how these coatings stack up for typical Kiwi projects.

Comparing Common ACM Panel Coatings

The finish you choose has a direct impact on the panel's lifespan and appearance. While budget options exist, premium coatings are almost always the right call for external use in New Zealand's climate.

| Coating Type | Key Benefit | Best For | Typical Lifespan |

|---|---|---|---|

| PVDF | Exceptional UV resistance and colour fastness. A proven track record of performance. | High-rise buildings, areas with intense sun exposure, and projects prioritising long-term colour stability. | 20+ years |

| FEVE | Excellent weatherability, wider gloss range, and superior chemical resistance. | Projects requiring a specific gloss level, architectural features, and areas exposed to salt spray or pollutants. | 20+ years |

| Polyester | A more budget-friendly option with good initial appearance and moderate durability. | Interior applications, low-rise buildings in sheltered locations, and short-term signage projects. | 5-10 years |

As you can see, investing in a premium PVDF or FEVE finish for any external ACM panel NZ application is a smart move that pays for itself in longevity and performance.

Beyond Solid Colours: Specialty Finishes

But the creative potential of ACM panels doesn't stop at solid colours. Modern coating technology opens up a whole world of specialty finishes that can convincingly mimic natural materials or create stunning visual effects.

- Metallic Finishes: These add a real sense of depth and sophistication. They play with the light, creating a dynamic surface that shifts and changes as the sun moves across the sky.

- Woodgrain Effects: You can get the warm, inviting look of timber without the constant maintenance—no more worrying about warping, rot, or pests.

- Prismatic & Colour-Shifting Finishes: These "chameleon" panels are incredible, changing colour depending on your viewing angle. They make for a truly unforgettable and contemporary architectural statement.

These options give architects and designers huge freedom to achieve a specific aesthetic while retaining all the practical benefits of a lightweight, durable, and fire-safe ACM panel system.

Sourcing and Installing ACM Panels in New Zealand

Alright, you’ve sorted through the core types and picked the perfect finish. Now comes the part where it all comes together: getting the panels on-site and onto the building. This is where your project’s success is really locked in, moving from theory to reality.

It’s about more than just finding a good price. You need to think about smart budgeting, finding a supplier you can trust, and making sure the installation itself is absolutely top-notch. Getting any of this wrong can lead to a world of pain, from budget blowouts to a non-compliant finish that won’t stand up to a New Zealand winter.

When we talk about cost, it's never just about the price per square metre. That's only part of the story. The final figure is a mix of things, and the biggest one is often the complexity of the job. A straightforward, flat wall is one thing. But a building with sweeping curves, dozens of window openings, and tricky corner details? That’s a whole different ball game, requiring more labour, specialised gear, and a much bigger budget.

Key Questions for Your ACM Panel Supplier

Choosing the right supplier is arguably one of the most critical decisions you'll make. This isn't just a transaction; it's about finding a partner who genuinely understands New Zealand's tough building regulations. A good supplier is your first line of defence against non-compliant materials.

Before you even think about signing a purchase order, you need to ask some hard questions and get the answers in writing.

- Can you show me the ISO 5660-1 test certificate? This is a deal-breaker. Insist on seeing a current certificate from a recognised lab for the exact panel you’re buying. No substitutions, no excuses.

- What’s the warranty on the panel? Look for a solid warranty of 15 years or more. This should cover both the finish—against things like excessive colour fade—and the panel's structural integrity, like delamination.

- Is this system Codemark certified or BRANZ appraised? While not a legal must-have for every project, these third-party certifications are a huge plus. They give you independent assurance that the product has been rigorously tested and meets NZ Building Code standards.

- What technical support do you provide? A reputable supplier won’t just drop the panels at the gate. They should provide detailed installation guides and be available to offer technical advice to ensure their product performs as it should.

Taking the time to do your homework here is the best insurance policy for your project. A supplier who can confidently answer these questions isn’t just selling a product; they’re demonstrating a commitment to quality and compliance that will protect your investment for years to come.

The Critical Role of Licensed Installers

Here’s a hard truth: you can have the best, most compliant ACM panel on the market, but if it’s installed poorly, it’s practically worthless. A botched installation can lead to everything from frustrating leaks and mould to the catastrophic failure of panels coming loose in a storm.

This is precisely why you can't cut corners with installation. Using a licensed or certified installer isn't just a 'nice to have'—it's absolutely essential for a safe, weatherproof, and long-lasting result.

A true professional understands the nuances of the system. They know how to account for the natural expansion and contraction of the panels in our fluctuating climate, how to create watertight seals that last, and how to fix the facade securely back to the building's main structure. They work to the manufacturer’s specs and the NZS 4284 standard for weather tightness.

Take a product like Indurabond Aluminium Composite Panels, for example. It's a system designed with low-rise New Zealand buildings in mind, featuring a fire-rated core and tough coatings proven to handle our conditions. That system is backed by a 15-year warranty, but that warranty hinges on one key condition: installation by licensed professionals. You can learn more about their tested performance and see how it's been used on projects from Auckland to the Waikato.

Ultimately, hiring a certified installer gives you peace of mind. Their work is backed by a workmanship guarantee, ensuring the cladding performs as intended. It’s your ticket to sailing through the final inspection, getting your Code Compliance Certificate, and avoiding costly defects down the track.

Common Questions About ACM Panels in New Zealand

Even with a good handle on the regulations, a few common questions always pop up when you're planning a project using ACM panels in NZ. Let's tackle some of the most frequent ones we hear from architects, builders, and property owners.

Are All ACM Panels Banned in New Zealand?

This is probably the biggest misconception out there. The short answer is no, there is no blanket ban on ACM panels in New Zealand.

The rules are actually quite specific. They target panels with a highly combustible polyethylene (PE) core, which are now rightly prohibited on most multi-level buildings.

On the other hand, fire-rated (FR) ACM panels are fully compliant and used all the time. These panels are engineered with a high-mineral-content core that's designed to resist fire, making them a perfectly safe and legal option when they're specified and installed correctly as part of a tested system.

How Do I Check if My Existing Building Is Compliant?

Figuring out what's on an older building takes a bit of detective work. If the building was built or re-clad after the code changes in early 2017, it's almost certain that compliant, fire-rated panels were used.

For buildings older than that, your first stop should be the original construction documents or council consent files. If you can't get your hands on those, the only foolproof way is a physical check. A qualified building surveyor or facade engineer can take a small, discreet sample of a panel to analyse its core and confirm its fire rating.

You can't just eyeball it. Both compliant and non-compliant panels can look identical from the outside, so identifying the core material is the only way to be certain.

What's the Average Cost of ACM Panels?

The price for an ACM panel in NZ can swing quite a bit depending on what you choose. A fire-rated (FR) core will cost more than a standard PE one, and if you're after specialty finishes like metallics or woodgrains, expect to pay a premium over standard solid colours.

As a rough guide, the raw material can cost anywhere from $80 to over $180 per square metre. But that's just the panel itself. The real costs come in with fabrication and installation. A complex, curved facade with lots of fiddly corners and window openings will demand a lot more labour and specialised gear than a simple flat wall, and that will be reflected in the final quote.

How Long Do ACM Panels Last in the NZ Climate?

Durability is where high-quality ACM panels really shine. When you specify a premium coating like PVDF or FEVE, they're built to handle New Zealand’s tough climate—especially our intense UV rays and salty coastal air.

Most reputable suppliers back their products with solid warranties, often for 15 to 20 years. This typically covers the finish against major fading or chalking and the panel itself against delamination, as long as it’s been installed by a certified professional and gets a regular clean.

At SONI DESIGN, we specialise in bringing your architectural and branding visions to life with high-quality materials and expert craftsmanship. Whether you need striking signage or a complete facade solution, our team is here to help you navigate your options and create something truly exceptional. Let's build your story together.

Leave a Comment

Stay home & get your daily

needs from our shop

Start You'r Daily Shopping with Nest Mart

Best prices & offers

Orders $50 or more

Free delivery

24/7 amazing services

Great daily deal

When you sign up

Wide assortment

Mega Discounts

Easy returns

Within 30 days